- Konu Başlıkları

- The Genesis: Design and Prototyping a 3D Printer

- The Production Line: Assembling the Future of Fabrication

- Component Sourcing and Supply Chain Management

- Assembly and Integration

- Rigorous Quality Control: Ensuring Peak Performance

- Market Entry: Packaging, Distribution, and Beyond

- Innovations and Future Trends in 3D Printer Production

- Automation and Robotics in Assembly

- Modular Design and Customization

- Sustainable Manufacturing Practices

- The Economic Impact and Global Landscape of 3D Printer Production

- Conclusion: The Engine Behind the Additive Revolution

- Frequently Asked Questions About 3D Printer Production

In a world rapidly embracing additive manufacturing, the focus often lies on what 3D printers can create – from intricate prototypes to complex end-use parts. But how often do we stop to consider the fascinating journey of the 3D printer itself? 3D printer production is a sophisticated blend of engineering, material science, and precision manufacturing, transforming raw components into the revolutionary machines we use today. This comprehensive guide will take you behind the scenes, exploring the intricate process of how these innovative devices are designed, assembled, and brought to market, ensuring they meet the high demands of a global industry.

[widget-131]

The Genesis: Design and Prototyping a 3D Printer

Before a single screw is turned on an assembly line, a 3D printer begins its life as a concept, meticulously designed to meet specific market needs or technological advancements. This initial phase involves extensive research and development (R&D), where engineers and designers collaborate to define the printer’s specifications, functionality, and aesthetics.

- Concept & Feasibility: Identifying market gaps, user needs, and technological possibilities.

- CAD Modeling: Creating detailed 3D computer-aided design (CAD) models of every component and the complete assembly. This is where the virtual blueprint takes shape.

- Component Selection: Sourcing or designing specialized parts, including stepper motors, hot ends, print beds, extruders, control boards, and structural frames. Each component's compatibility and performance are critical.

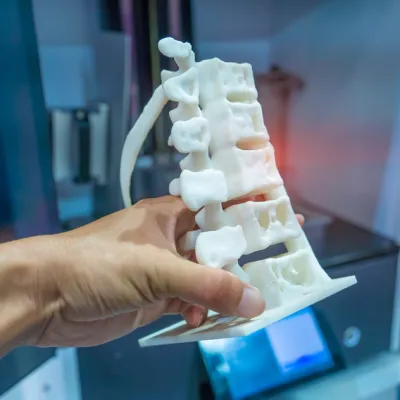

- Prototyping & Testing: Early versions of the printer are built, often utilizing existing 3D printers or traditional manufacturing methods to create initial 3D prototype production. These prototypes undergo rigorous testing to identify flaws, optimize performance, and refine the design. Iterative testing is key to robust final products.

Reliability and user-friendliness are paramount during this stage, as even minor design flaws can lead to significant production challenges and customer dissatisfaction later on. This meticulous design phase lays the groundwork for efficient and high-quality manufacturing.

The Production Line: Assembling the Future of Fabrication

Once the design is finalized and validated through prototyping, the 3D printer moves to the production phase. This is where individual components come together on highly organized assembly lines, transforming abstract designs into tangible machines. The scale and automation of these lines vary significantly, from small-batch artisanal production to large-scale industrial manufacturing.

Component Sourcing and Supply Chain Management

A critical aspect of 3D printer production is managing a complex global supply chain. Manufacturers source components from various specialized suppliers worldwide, ensuring quality, cost-effectiveness, and timely delivery. This includes everything from electronic components and custom extrusions to specialized nozzles and motion systems.

Effective supply chain management minimizes delays, controls costs, and ensures the continuous flow of materials, a cornerstone of efficient 3D printer production. A robust supply chain builds resilience against global disruptions, ensuring stable output.

Assembly and Integration

The assembly process typically involves a series of stations, each responsible for adding specific components or sub-assemblies. For mass-produced desktop 3D printers, this often involves a degree of automation, with robots handling repetitive tasks, while human technicians oversee complex integration and quality checks.

- Frame Assembly: Building the structural skeleton that houses all other components.

- Motion System Integration: Installing stepper motors, belts, lead screws, and linear rails that enable precise movement of the print head and bed.

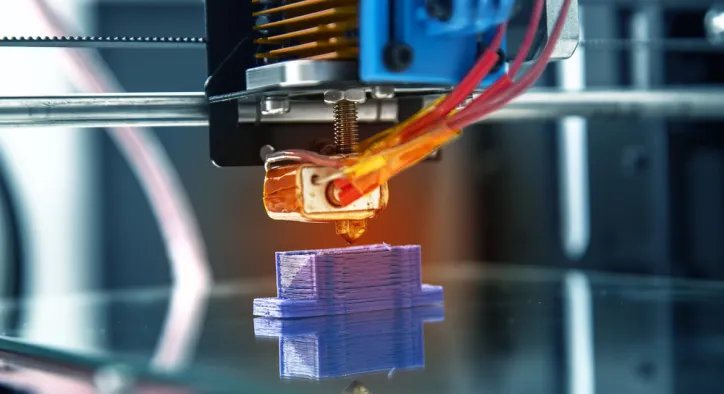

- Extruder & Hot End Assembly: Putting together the crucial components responsible for melting and depositing filament.

- Electronics Integration: Installing the main control board, wiring, sensors, and power supply. This requires meticulous attention to detail to prevent electrical issues.

- Final Assembly & Enclosure: Mounting the exterior panels, doors, and any other aesthetic or protective elements.

The precision required at each step cannot be overstated. Misalignments of even a fraction of a millimeter can significantly impact print quality and machine reliability. This commitment to precision defines leading manufacturers.

Rigorous Quality Control: Ensuring Peak Performance

Quality control (QC) is not a single step but an overarching philosophy integrated throughout the entire 3D printer production process. From incoming material inspection to final product testing, QC ensures that every printer leaving the factory meets stringent performance and safety standards.

Initial QC checks are performed on individual components as they arrive from suppliers. During assembly, each sub-assembly often undergoes testing before being integrated into the larger system. The most comprehensive testing occurs after final assembly:

- Calibration & Alignment: Ensuring all axes are perfectly aligned, bed leveling is accurate, and motion systems operate smoothly.

- Functional Testing: Running test prints to verify extrusion, heating, cooling, and overall print quality. This often involves printing a standard test model to check for common issues.

- Safety Checks: Verifying electrical safety, thermal regulation, and structural integrity.

- Firmware Flashing & Software Installation: Loading the latest firmware and ensuring all software components are correctly installed and configured.

This multi-layered QC approach is vital for ensuring the longevity and precision that users expect from their 3D printers. It builds trust in the brand's reliability and performance. Continuous improvement loops based on QC data are also essential.

Market Entry: Packaging, Distribution, and Beyond

Once a 3D printer passes all quality control checks, it’s ready for packaging and distribution. This phase focuses on protecting the delicate machinery during transit and efficiently getting it to customers worldwide.

- Packaging: Designing robust, protective packaging that minimizes the risk of damage during shipping. This often includes custom foam inserts and reinforced cardboard.

- Logistics & Distribution: Managing inventory, warehousing, and shipping channels to deliver printers to retailers, distributors, or directly to end-users. Global logistics networks are key for wide market reach.

- Post-Sale Support: Offering customer service, technical support, warranty services, and spare parts. This is crucial for building a strong brand reputation and ensuring customer satisfaction.

The journey doesn't end when the printer reaches the customer. Ongoing support, firmware updates, and community engagement contribute significantly to the overall user experience and brand loyalty. This is where a company’s commitment to E-E-A-T truly shines.

Innovations and Future Trends in 3D Printer Production

The 3D printer production landscape is constantly evolving, driven by technological advancements and increasing market demand. Several key trends are shaping the future of how these machines are made:

Automation and Robotics in Assembly

As production volumes increase, the adoption of advanced robotics and automation in assembly lines is accelerating. This leads to greater efficiency, reduced labor costs, and improved consistency in manufacturing, especially for repetitive tasks.

Smart factories utilizing AI-driven systems are becoming more common, enabling real-time monitoring and optimization of the entire production process. This also ties into advancements in 3D printing service delivery, as the underlying technology improves.

Modular Design and Customization

Increasingly, 3D printers are being designed with modularity in mind. This allows for easier assembly, simplified repairs, and greater customization options, enabling manufacturers to cater to diverse user needs without completely redesigning entire systems. It also supports faster iterations in production.

Sustainable Manufacturing Practices

With growing environmental consciousness, 3D printer manufacturers are exploring more sustainable production methods. This includes using recycled materials for components, optimizing energy consumption in factories, and implementing closed-loop manufacturing processes to minimize waste. The focus is shifting towards an eco-friendly production footprint.

The Economic Impact and Global Landscape of 3D Printer Production

The production of 3D printers is a significant segment of the global additive manufacturing market, driving innovation and economic growth. Major players span across continents, with significant production hubs in Asia, Europe, and North America. This global competition fosters rapid technological advancement and competitive pricing, benefiting end-users.

The market for 3D printers continues to expand, driven by industries like automotive, aerospace, healthcare, and consumer goods. This demand fuels further investment in research, development, and advanced manufacturing capabilities, creating a virtuous cycle of innovation and growth. Understanding this global landscape is key for both producers and consumers.

Conclusion: The Engine Behind the Additive Revolution

3D printer production is far more than just assembling parts; it's a meticulously engineered process that brings the power of additive manufacturing to the world. From the initial spark of an idea and rigorous prototyping to precision assembly, stringent quality control, and strategic market distribution, every stage is crucial.

As the industry continues to evolve, driven by automation, modularity, and sustainability, the production of 3D printers will remain at the forefront of technological innovation. Understanding this complex journey not only highlights the ingenuity involved but also underscores the dedication required to deliver the reliable, high-performance tools that are shaping our future.

[widget-136]

Frequently Asked Questions About 3D Printer Production

- What is the primary goal of 3D printer production?

The primary goal is to efficiently and reliably manufacture 3D printing machines that meet design specifications, perform consistently, and satisfy market demands for various applications. - What are the main stages in manufacturing a 3D printer?

The main stages include R&D/Design, Component Sourcing, Assembly, Quality Control, and Packaging/Distribution. - Are 3D printers made using other 3D printers?

While some non-critical components or prototypes during the R&D phase might be 3D printed, the core structural and functional parts of mass-produced 3D printers are manufactured using traditional industrial methods (e.g., injection molding, CNC machining) for precision, durability, and cost-effectiveness. - How do manufacturers ensure the quality of 3D printers?

Quality is ensured through multi-stage checks: incoming component inspection, in-process assembly checks, rigorous post-assembly functional testing, calibration, and long-term reliability tests. - What are the biggest challenges in 3D printer manufacturing?

Key challenges include managing complex global supply chains, maintaining high precision during assembly, controlling manufacturing costs, and adapting to rapid technological advancements.