- Konu Başlıkları

- The Use of 3D Printing in Engineering: The Power of 3D Printing in Engineering

- Areas of Use of 3D Printing in Engineering

- Automotive Industry

- Aerospace Engineering

- Construction Sector

- Acceleration and Improvement of Design Processes

- Production and Cost Advantages

- The Future of 3D Printing in Engineering

The Use of 3D Printing in Engineering: The Power of 3D Printing in Engineering

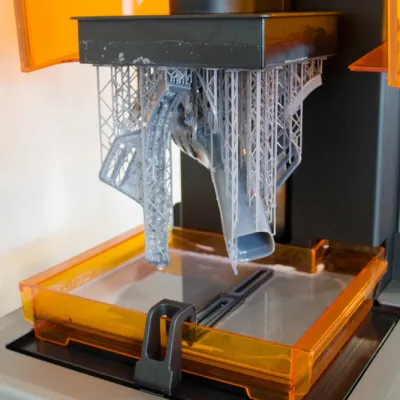

While technology is advancing rapidly, there are also revolutionary changes in the engineering world. One of these changes is the use of 3D printing in engineering. This technology, which goes beyond traditional production methods, is starting a new era in engineering services. The use of 3D printers in engineering services not only speeds up production processes, but also reduces costs and makes the design process more efficient.

Today, the use of 3D in engineering is much more widespread and is applied in different areas. So, how is this new technology used in engineering and how does it make a big difference? In this article, the use of 3D printing in engineering will be examined in depth, and its important advantages and practical applications will be discovered.

[widget-131]

Areas of Use of 3D Printing in Engineering

The use of 3D printers in engineering covers a wide range from design to prototyping. 3D printing technology is used in many fields such as industrial designs, aircraft engineering, the automotive sector, and civil engineering. 3D printers offer revolutionary innovations in the engineering world and provide serious efficiency increases in the design process.

The use of 3D printers, especially in engineering services, enables prototypes to be produced quickly and designs to be tested in the early stages. This allows engineers to detect design errors at an early stage and provides significant savings in the production process. At the same time, the use of 3D printers in engineering makes it easier to produce complex geometries, so engineers can develop more innovative and original designs.

Automotive Industry

The use of 3D in engineering is rapidly becoming popular in the automotive sector. Designers use 3D printers to quickly prototype vehicle parts. In this way, the development time of new model vehicles is shortened and more efficient tests can be performed. In addition, the use of 3D printers in engineering is ideal for small batch production, so it is possible to produce more original designs of vehicles.

Aerospace Engineering

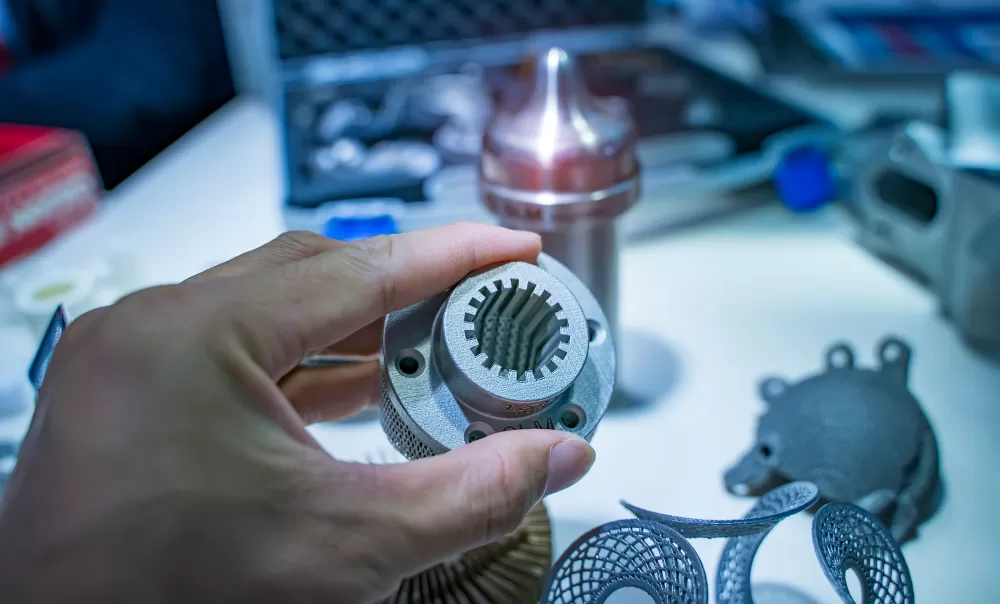

The use of 3D printers in aircraft engineering allows the production of lighter and more durable parts. While complex geometric structures can be too difficult and expensive to produce with traditional methods, these parts can be produced more quickly and economically thanks to 3D printers. The use of 3D printers in engineering services enables the production of tested, safe and high-performance parts, especially for aircraft engines and aircraft structures.

Construction Sector

The use of 3D printing in engineering is also revolutionizing the construction sector. The use of 3D printers in engineering, especially for the rapid construction of buildings, allows architects to realize their designs more freely. In addition, civil engineers can complete projects in a shorter time and at a lower cost thanks to the use of 3D printers in engineering services. 3D printers allow the creation of building materials by direct printing, which saves time and labor.

Acceleration and Improvement of Design Processes

The use of 3D printing in engineering makes the design process faster and more flexible. In traditional production methods, prototyping a design is a long process, which makes it difficult for engineers to quickly implement their innovative ideas. However, this process becomes much faster with 3D printers. Thanks to the use of 3D printers in engineering, engineers can transform their designs into physical models in a very short time and test them quickly.

In addition, the use of 3D in engineering allows prototypes to be not only tested but also improved. Errors in the design phase are detected faster and these errors are corrected with minimum cost. This increases efficiency in engineering processes and higher quality products emerge in shorter periods of time.

Production and Cost Advantages

Another important issue is the cost advantages provided by the use of 3D printers in engineering in production processes. In traditional production methods, mold making and excessive labor are required, especially for the production of complex parts. However, the use of 3D in engineering eliminates the need for molds and allows you to perform these processes at much more affordable costs.

In addition, thanks to the use of 3D printing in engineering, there is less material waste. Designs are created using only the necessary amount of material, which provides both environmental and economic benefits. This feature significantly reduces costs, especially in the industrial field.

[widget-136]

The Future of 3D Printing in Engineering

The use of 3D printing in engineering continues to revolutionize the world of engineering. Rapid prototyping, low-cost production, less material waste and innovative designs are the main advantages offered by this technology. The use of 3D printers in engineering services plays a critical role not only for industrial designs, but also for the more efficient and faster implementation of large projects.

In the future, the use of 3D in engineering is expected to become even more widespread. This technology allows engineers to create freer designs without limiting their imagination, while at the same time accelerating processes and increasing efficiency, leading to major changes in the sector.

The use of 3D printing in engineering is a candidate to be one of the cornerstones of future engineering practices, if not a revolution in today's engineering world.