- Konu Başlıkları

- Why Choosing the Right 3D Printing Service Matters

- Key Criteria for Choosing 3D Printer Production Services

- 1. Technical Capabilities

- 2. Material Options

- 3. Quality Assurance & Tolerances

- 4. Lead Time & Scalability

- 5. Pricing Transparency

- Evaluating a Provider's Portfolio and Experience

- Communication & Customer Support

- The Erlas Global Approach to 3D Production Services

- Red Flags to Avoid When Choosing a Service

- Checklist for Choosing a 3D Printing Service

- Conclusion

- Frequently Asked Questions

Selecting the right 3D printer production service is a critical decision that can significantly influence the quality, speed, and cost-effectiveness of your product development process. Whether you are a project manager launching a new design or a manufacturer optimizing production workflows, the choice of service provider will shape your outcomes and timeline.

This comprehensive guide will help you navigate the key factors to consider, including technical capabilities, quality standards, material options, pricing, and vendor reliability. We’ll also explore Erlas Global’s structured production process and how it stands out as a trusted partner in additive manufacturing.

[widget-131]

Why Choosing the Right 3D Printing Service Matters

With countless vendors offering 3D printer production services, the selection process can quickly become overwhelming. Each provider brings different technologies, skill sets, and workflows to the table. A poorly chosen service may result in delays, dimensional inaccuracies, poor surface finishes, or prototypes that fail during testing.

This is why an informed and systematic approach to selecting a provider is not only wise—it’s essential.

Key Criteria for Choosing 3D Printer Production Services

Below is a checklist of critical factors to evaluate before choosing a 3D printing partner:

1. Technical Capabilities

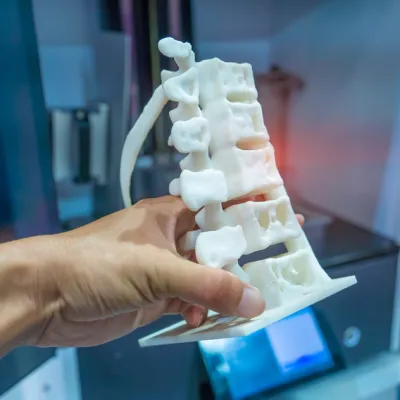

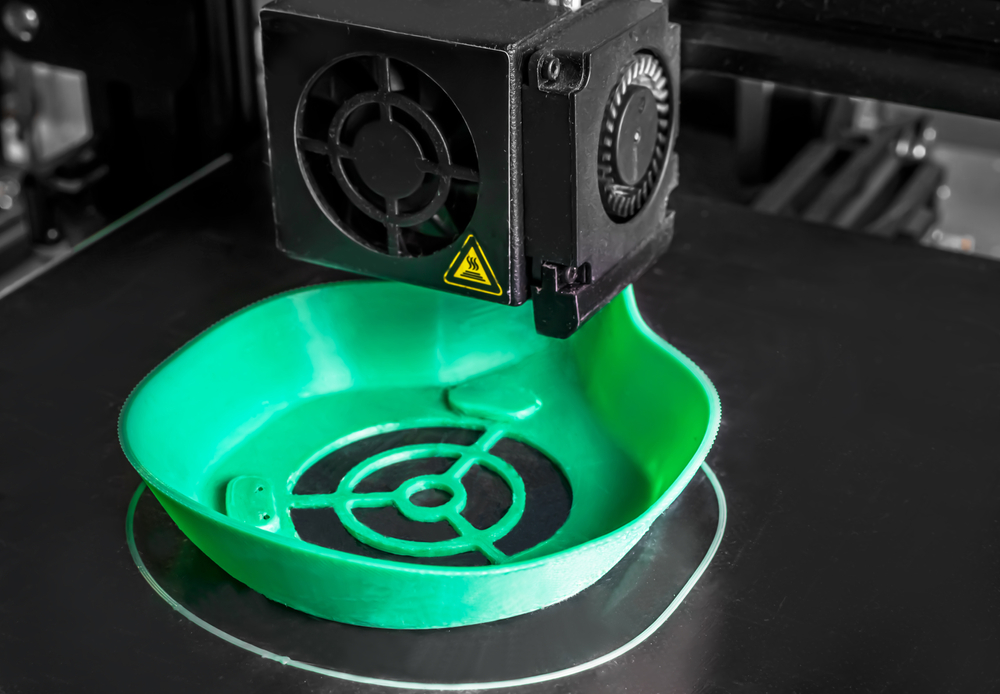

Begin by understanding what kind of 3D printing technologies the vendor offers. The most common processes include:

- FDM (Fused Deposition Modeling) – great for low-cost, quick drafts.

- SLA (Stereolithography) – ideal for smooth, detailed models.

- SLS (Selective Laser Sintering) – useful for functional prototypes and mechanical parts.

- Metal 3D Printing – used for high-strength or end-use parts.

The chosen process should align with your project requirements. For instance, if you need intricate internal geometries or tight tolerances, the service should support that level of detail and precision.

2. Material Options

Material compatibility is another deciding factor. Evaluate whether the provider offers the specific materials needed for your application, such as:

- PLA, ABS, PETG for general use

- Resin for fine detail

- Nylon, TPU for flexibility or strength

- Metal alloys for industrial parts

An experienced provider like Erlas Global’s 3D printer production service typically offers guidance on material selection based on end-use performance, durability, and environmental exposure.

3. Quality Assurance & Tolerances

Ask vendors about their tolerance levels and post-processing capabilities. High-end services will:

- Provide documentation of quality checks

- Use industrial-grade printers

- Offer surface finishing and dimensional inspection

Look for ISO certifications or process documentation that validate the company’s commitment to consistent quality.

4. Lead Time & Scalability

Turnaround time is vital, especially if you're working within tight deadlines. Inquire about:

- Average print lead times

- Batch production capabilities

- Availability for urgent jobs

Scalability is also important. Can the provider handle a transition from prototyping to small-batch or mass production?

5. Pricing Transparency

While cost shouldn’t be the only factor, it certainly plays a role. Be cautious of vendors that provide vague pricing or excessive minimum order requirements. A reliable partner will offer:

- Clear price breakdowns

- No hidden setup fees

- Cost options based on material or finish

Request a sample quote and compare it with others to assess value, not just price.

Evaluating a Provider's Portfolio and Experience

Ask for previous case studies or portfolios. Experienced services like 3D prototype production at Erlas Global often showcase:

- Prototypes across various industries

- Functional testing results

- Real-world applications

Feedback from past clients can offer insights into how problems were handled, how communication was maintained, and how responsive the service provider was during the project.

Communication & Customer Support

Transparent communication can save time and prevent costly misunderstandings. Look for services that offer:

- Dedicated account managers or engineers

- Design-for-manufacturing feedback

- Clear and responsive communication channels

Whether it’s an email update or a project portal, knowing your prototype's status brings peace of mind and confidence.

The Erlas Global Approach to 3D Production Services

Erlas Global takes a structured and consultative approach to 3D printing service delivery. Each project begins with a requirements consultation, where key details such as geometry, material, mechanical stress, and intended use are clarified.

Once the project moves to production, clients receive:

- Timeline estimations

- Real-time updates

- QA documentation

- Functional testing options

By focusing on collaborative design reviews and rapid iteration cycles, Erlas Global minimizes friction and maximizes value.

Red Flags to Avoid When Choosing a Service

Some warning signs that a provider may not be the best fit include:

- Lack of project portfolio or references

- No clear contact person or support line

- Overly generic responses to technical questions

- Limited material selection or outdated printers

- Inflexible order sizes or rigid pricing

If a provider fails to answer your detailed questions, it might be best to look elsewhere.

Checklist for Choosing a 3D Printing Service

Use this summary checklist when evaluating a potential service:

✅ Do they support the required 3D printing technology?

✅ Do they offer the materials needed for your prototype?

✅ What tolerances and quality controls are in place?

✅ How quickly can they deliver prototypes or parts?

✅ Are prices transparent and reasonable?

✅ Do they have a proven track record?

✅ Is customer support knowledgeable and responsive?

Conclusion

Choosing the right 3D printer production service is a critical part of product development success. From technical capabilities and materials to turnaround time and quality standards, every factor plays a role in ensuring your prototype or part meets its intended purpose.

By following a structured selection process and prioritizing providers like Erlas Global—who combine experience with customer-centric services—you’ll reduce risks, optimize costs, and gain a reliable partner in innovation.

Don't leave your project outcomes to chance. Make informed decisions that move your ideas forward with precision and confidence.

[widget-136]

Frequently Asked Questions

What is the most important factor when choosing a 3D printing service?

It depends on your project. However, quality assurance and technical compatibility often top the list.

How do I know if a 3D printing provider is reliable?

Look for ISO certifications, positive client testimonials, and a detailed portfolio of past projects.

Can I use the same provider for prototyping and production?

Yes, many providers like Erlas Global offer both small-batch and scalable production services.

Are there cost differences between printing technologies?

Yes. FDM is usually cheaper, while SLA or SLS may cost more but offer better surface quality and strength.

Do I need technical drawings or CAD files before contacting a provider?

Most providers require a 3D CAD file, but many offer design assistance if you’re in the early stages.