- Konu Başlıkları

- Cost Speed Savings and 3D Privilege in Product Development - 3D Printing Aviation Companies

- 3D Printing Reduces Costs for Aviation Companies 3d Printing in Aviation Sector

- Using 3D Printers in Aviation Saves Time

- 3D Printing Offers Design Flexibility in the Aviation Sector

- 3D Printing Creates Less Waste and Sustainability in the Aviation Sector

- 3D Printing Provides Long-Term Investment and Competitive Advantage for Aviation Companies

Cost Speed Savings and 3D Privilege in Product Development - 3D Printing Aviation Companies

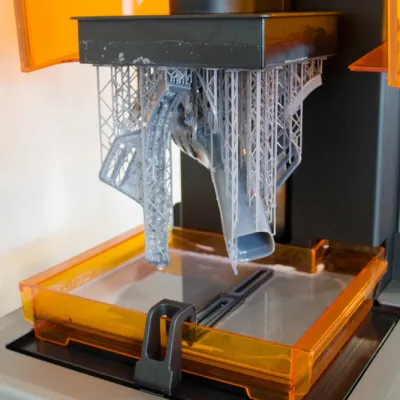

The aviation sector is an industry known for its high precision and safety requirements. Each aircraft part carries the most valuable assets of humans and for this it must be error-free, durable and safe. In addition, innovation, speed, efficiency and low costs are also critical factors in the aviation sector. At this point, 3D printing offers a revolutionary solution for aviation companies. The use of 3D printing technology in the aviation sector provides important advantages such as reducing costs, accelerating production times and increasing flexibility in design.

So, how does 3D printing offer a great opportunity for the aviation sector, what are the savings and speed advantages provided by the use of 3D printers in aviation? All the details about 3d printing aviation companies are here...

[widget-131]

3D Printing Reduces Costs for Aviation Companies 3d Printing in Aviation Sector

In the aviation sector, keeping costs under control is an important goal for both manufacturers and airlines. 3D printing can significantly reduce costs for aviation companies. While traditional production methods require the production of a large number of parts at high costs, parts can be produced with less material thanks to 3D printing in the aviation sector, and as a result, costs decrease. 3D printing in the aviation sector has revolutionized part manufacturing, offering innovative solutions to improve performance and reduce operational costs.

In particular, it is possible to optimize parts in the 3D printer and aviation sector. Such optimizations can be made with traditional methods, but they are usually more expensive and time-consuming. 3D printing increases the performance of aircraft by providing the opportunity to produce lighter, more durable and more efficient parts in terms of design. 3D printing in aviation sector, aviation companies achieve long-term savings by providing lower production costs and lower fuel consumption.

Another important cost advantage for 3D printing aviation companies is how 3D printing aviation technology can be used in the production of spare parts. The use of 3D printers in aviation allows spare parts to be produced only when needed. Spare part production usually leads to large stocking costs, but with 3D printers, parts can be produced on demand. This significantly reduces logistics and warehouse costs.

Using 3D Printers in Aviation Saves Time

The use of 3D printers in aviation provides great speed, especially in aircraft production and repair. While it can take weeks or even months to produce a part in traditional production methods, 3D printing can produce the same part in a few hours for aviation companies. This speed is critical for adapting to the dynamic structure of the aviation industry.

Thanks to 3D printing in the aviation sector, it is possible to quickly produce and test prototypes used in aircraft production. Rapid prototyping offered by 3D printers and aviation technology enables designs to be developed quickly and allows engineers to make changes quickly. This speed provides a great time saving in the production process and makes aircraft production processes more efficient.

Similarly, 3D printing offers a significant advantage in the aviation sector in repairing malfunctions in aircraft. Waiting times for spare part production are reduced, thus minimizing the time it takes for aircraft to land. This increases the operational efficiency of airline companies and allows aircraft to fly more. By implementing 3D printing aviation sector can quickly prototype parts, enabling faster development cycles and reducing production time.

3D Printing Offers Design Flexibility in the Aviation Sector

3D printing aviation technology allows designers to create unique and complex designs that were not previously possible. Complex geometries that cannot be made with traditional production methods can be easily produced with 3D printing in the aviation sector. Designs can be optimized to best balance the effects of forces exposed during flight in aircraft components. In addition, more unique and functional solutions can be produced in the interior designs of aircraft on behalf of 3D printing aviation companies.

This design flexibility offered by 3D printers and aviation technology allows aircraft manufacturers to develop more innovative, efficient and environmentally friendly designs with engineering solutions. The use of 3D printers in aviation enables the production of components that are optimized in terms of both engineering and aesthetics. This design freedom allows the aviation sector to produce lighter, more environmentally friendly and more efficient aircraft in the future.

3D Printing Creates Less Waste and Sustainability in the Aviation Sector

Another important advantage is that 3D printing aviation technology can be environmentally friendly. In traditional production processes, there can be a large amount of material waste. However, 3D printing aviation companies produce using only the necessary material. This minimizes the amount of waste and reduces environmental impact.

3D printing in the aviation sector offers a more sustainable production process as parts can be produced with only the necessary material. Thus, 3D printing and the aviation industry can switch to more environmentally friendly production processes and reduce the carbon footprint in the sector. 3D printing aviation sector has revolutionized part manufacturing, offering innovative solutions to improve performance and reduce operational costs. 3D printing in aviation sector is here.

[widget-136]

3D Printing Provides Long-Term Investment and Competitive Advantage for Aviation Companies

3D printing offers a great opportunity for the aviation sector. This technology not only reduces costs, but also provides aviation companies with important advantages such as fast production, design flexibility and sustainability. The use of 3D printers in aviation provides a significant competitive advantage for companies that follow the latest innovations in the sector. 3D printing aviation companies can take their place in the market faster and gain an advantage over their competitors by producing faster and at lower costs.

The opportunities offered by 3D printing and aviation technology drive innovation in this field and pave the way for long-term investments for future projects. By using 3D printing aviation technology, aviation companies not only reduce costs, but also produce more efficient and safer aircraft, increase their operational efficiency and reinforce their leadership in the sector. If you are looking for 3D printing aviation company solutions, you can contact us to discover how you can integrate this revolutionary technology. Reduce costs and increase your production speed!