- Konu Başlıkları

- 3D Electronic Prototype Printing: A New Era in Technology

- What is 3D Electronic Prototype Printing?

- How Does 3D Electronic Prototype Printing Method Work?

- Advantages of 3D Electronic Prototype Printing

- Rapid Production: Deliver Prototypes on Time

- Low Cost: Produce More with Economical Solutions

- Design Flexibility: Offer Complex and Special Solutions

- Environmentally Friendly Production: Design with Sustainable Technology

- Application Areas of 3D Electronic Prototype Printing

- Fast and Sustainable Solutions: 3D Electronic Product Printing

3D Electronic Prototype Printing: A New Era in Technology

Offering fast and precise solutions in electronic product design, 3D electronic prototype printing has become one of the indispensable methods of prototype production today. This technology allows complex electronic circuits and components to be modeled and tested quickly, while greatly accelerating product development processes. The 3D electronic prototype printing method enables the implementation of innovative projects by offering flexibility in both the design and production stages.

[widget-131]

What is 3D Electronic Prototype Printing?

3D electronic prototype printing is a production technology used for the physical modeling of electronic circuits and products. This method modernizes traditional PCB (Printed Circuit Board) design processes, allowing complex circuits and components to be created layer by layer. 3D prototype printing is ideal for both rapid prototype development and low-volume production.

Quick testing of the functionality of electronic products.

Easy creation of detailed and complex circuits.

Ability to revise the design by receiving rapid feedback during the 3D prototype printing phase.

How Does 3D Electronic Prototype Printing Method Work?

The 3D electronic prototype printing method consists of several stages from design to production:

Digital Design: The electronic product is designed in a digital environment with CAD software. This model is optimized for the 3D printing device.

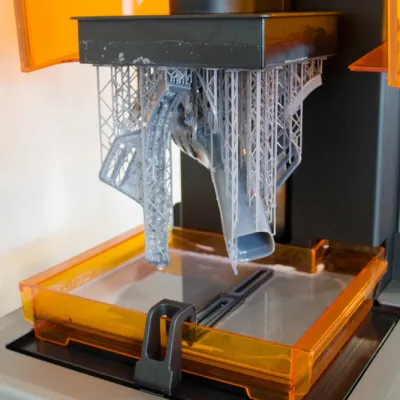

Additive Manufacturing: The printing device creates electronic components and circuit paths layer by layer, making the model physical.

Final Process: After the printing is completed, the model is cleaned and subjected to functionality tests.

This method offers an ideal solution especially for 3D electronic product printing.

Advantages of 3D Electronic Prototype Printing

3D electronic prototype printing service offers numerous advantages in both design and production processes. This technology, which is a fast, economical and environmentally friendly solution, makes a difference in electronic prototype production. Here are its main advantages:

Rapid Production: Deliver Prototypes on Time

3D electronic prototype printing method greatly accelerates the conversion of designs into physical prototypes. Processes that may take weeks in traditional production methods can be completed in a few days thanks to this technology. This speed prevents loss of time by optimizing product development processes.

Testing Opportunity: Fast production with 3D prototype printing allows the design to be tested in the early stages.

Efficiency in Project Processes: You can achieve effective results even in projects with tight timelines.

Market Advantage: 3D prototype printing allows products to be launched in a shorter time, creating an advantage in competition.

Low Cost: Produce More with Economical Solutions

3D electronic product printing offers an economical alternative with less material usage compared to traditional PCB production methods. This method provides a high cost advantage in low-volume production.

Material Savings: Only the required material is used, preventing waste.

No Mold Required: Expensive molds used in traditional methods are not required.

Small Quantity Production: During the 3D prototype printing stage, high-quality production is possible at low cost.

Design Flexibility: Offer Complex and Special Solutions

3D electronic prototype printing method transforms complex circuit designs into reality by providing design freedom. It offers creative solutions by overcoming the limitations of traditional manufacturing processes.

Complex Geometries: 3D prototype printing can easily produce challenging circuit paths and components.

Customization: Allows the design of special prototypes for different projects.

Precision: Thanks to 3D electronic product printing, even the smallest details are created precisely.

Environmentally Friendly Production: Design with Sustainable Technology

3D electronic prototype printing offers an environmentally friendly production process. This technology minimizes waste by using only the required material.

Waste Reduction: It creates less waste compared to traditional manufacturing processes.

Energy Efficiency: It minimizes environmental impacts by using less energy.

Sustainable Materials: Provides environmentally friendly solutions with recyclable material options.

These advantages make both your design and production processes more efficient with 3D electronic prototype printing service. With its speed, cost savings, design flexibility and environmentally friendly features, this technology is an indispensable tool in modern electronics production.

Application Areas of 3D Electronic Prototype Printing

3D electronic product printing is widely used in electronic product design and development processes. This technology has an important role in the following areas:

Electronic Product Development: Creating and testing prototypes of new products thanks to 3D electronic product printing.

Consumer Electronics: 3D electronic prototype printing service is used in the design of special electronic devices.

Education: Creating visual and practical learning materials for electronic engineering students.

Medical Electronics: Production of electronic prototypes of medical devices with 3D electronic product printing.

[widget-136]

Fast and Sustainable Solutions: 3D Electronic Product Printing

3D electronic prototype printing is a fast, flexible and innovative solution for modern electronic product design. This technology accelerates design processes and enables products to be launched in a shorter time. In addition, 3D electronic prototype printing service develops environmentally friendly solutions by offering sustainable production methods. As Erlas, we can take your projects to the next level with the innovative 3D electronic product printing solutions we offer. Thanks to our innovative work, you can optimize your design processes.