- Konu Başlıkları

- Transform Your Dreams into Reality with the Power of Technology!

- Why Is Prototyping with 3D Printers Important for Companies?

- Applications of 3D Prototype Manufacturing

- How Is Prototype Production with 3D Printing Done?

- Is Three-Dimensional Prototyping Costly?

- Prototype production with 3D printing saves costs!

- Key Advantages of 3D Prototyping

- A Budget-Friendly Option for Your Company!

Transform Your Dreams into Reality with the Power of Technology!

Today’s manufacturing processes focus not only on speed and cost optimization but also on innovation. This is where prototype production with 3D printing comes into play. 3D printers revolutionize all stages, from design to production, becoming indispensable for both individual users and globally operating companies. With consumer demands centering around customizable products, 3D rapid prototyping has emerged as an excellent alternative for creating customer-specific designs.

[widget-131]

Why Is Prototyping with 3D Printers Important for Companies?

Innovative designs and rapid product development are vital for companies operating in global markets. Prototype production with 3D printing offers businesses a fast and cost-effective solution, providing a competitive edge. Small and medium-sized enterprises can reach design and production capacities otherwise unattainable through traditional methods, enabling them to become global players. In short, prototyping with 3D printers is one of the most effective ways to turn dreams into reality.

Testing a design’s functionality before production minimizes risks. Prototype production with 3D printing allows for early detection of potential errors, reducing risks and preventing financial losses. If you're looking for innovative solutions at every stage of your production process, three-dimensional prototyping is the ideal tool for you.

Applications of 3D Prototype Manufacturing

Companies producing prototypes with 3D printers can create projects for various industries:

Automotive Industry:

Aerodynamic features and compatibility of vehicle parts can be quickly tested through prototyping with 3D printers.

Healthcare Industry:

Three-dimensional prototyping is widely used in developing medical devices, designing prosthetics, and even bioprinting organs.

Electronics and Technology:

3D prototype manufacturing is highly practical for circuit boards, sensor housings, and other electronic components.

Fashion and Art:

Prototype production with 3D printing offers artists and designers limitless possibilities for turning complex designs into reality.

How Is Prototype Production with 3D Printing Done?

The most crucial step in successful 3D prototype manufacturing is accurate design. CAD (Computer-Aided Design) software is frequently used in this process. After creating the design file, it is converted into an STL file that can be transferred to a 3D printer. Material selection is made based on the prototype's purpose and features. While plastics like ABS, PLA, and PETG are commonly used, metal, ceramic, and biomaterials are also options.

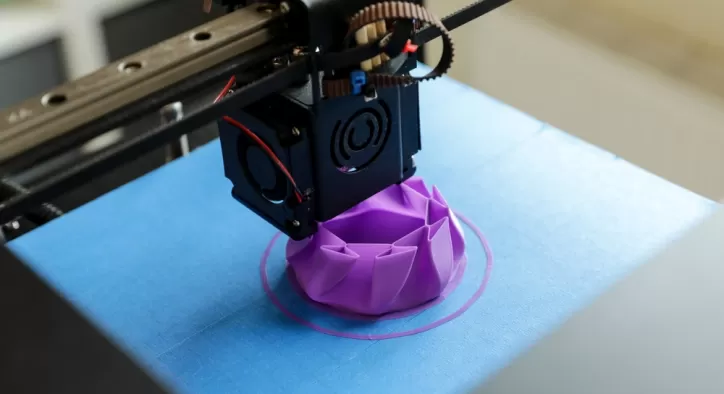

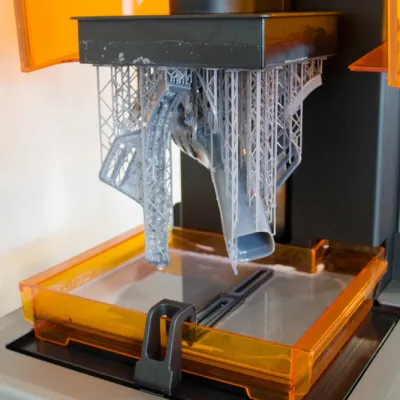

Once the material and design are selected, printer settings are optimized. Using an additive manufacturing method, the prototype is built layer by layer. Post-processing, such as sanding or painting, may be performed on the prototype's surface if needed. The prototype is then evaluated to test the design's functionality.

Is Three-Dimensional Prototyping Costly?

Several factors influence the cost of prototyping with 3D printers. Materials like PLA and ABS are typically affordable, while advanced materials like metal, ceramic, or specialized biomaterials are more expensive. Complex and detailed designs require longer print times and more material, which can increase costs.

Industrial-grade 3D printers offer high precision and durability but come with higher operational costs than desktop printers. Additionally, longer prototyping processes may lead to indirect costs such as increased electricity consumption.

Prototype production with 3D printing saves costs!

Producing multiple prototypes simultaneously, avoiding unnecessary details, and selecting materials suitable for the prototype’s purpose can reduce expenses.

Key Advantages of 3D Prototyping

3D rapid prototyping reduces processes that could take days or even weeks with traditional methods to just a few hours. This enables designers and engineers to test their ideas quickly. Traditional prototyping methods can be quite expensive due to mold creation and various manual processes. Prototype production with 3D printing minimizes material waste while delivering high-quality results at a lower cost. Three-dimensional printers can easily create complex geometric shapes, allowing designers to work without limitations. Prototyping with 3D printers prevents unnecessary material usage. Additionally, it allows for the use of recyclable materials, making it ideal for sustainable production.

[widget-136]

A Budget-Friendly Option for Your Company!

Although prototype production with 3D printing may seem costly as a technological alternative, it is highly advantageous in the long run due to the speed, flexibility, and cost savings it offers. Whether you are an individual user or a global business, you can maximize the benefits of 3D prototype manufacturing with proper planning and strategy.

At Erlas Global, we add value to companies operating locally and globally by providing prototyping services with 3D printers. We offer the best alternatives to help you optimize your workflows, production processes, and goals—essentially investing in your future. Contact Erlas Global for prototype production with 3D printing today!