- Konu Başlıkları

- A Revolution in Product Development! – Spare Part Production Meets 3D Technology

- 3D Spare Part Production Process

- Spare Part Production with 3D Printing in the Automotive Sector

- What are the Advantages of Spare Part Production with 3D Printing in the Automotive Sector?

- In Which Areas is Spare Part Production with 3D Printing Used?

- Is Spare Part Production with 3D Printing Costly?

- 3D Spare Part Production is Valuable for the Automotive, Aerospace and Medical Sectors!

A Revolution in Product Development! – Spare Part Production Meets 3D Technology

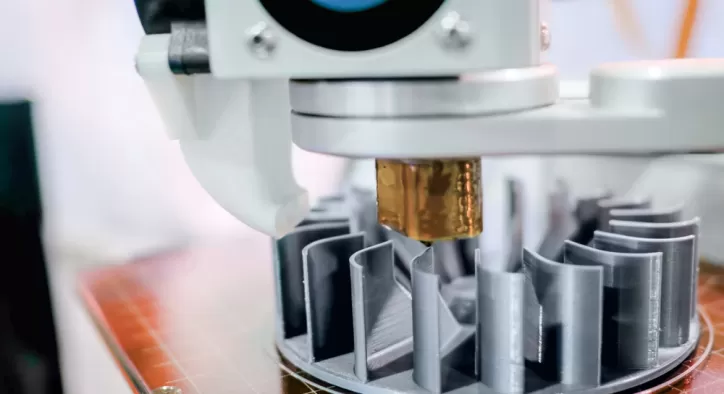

3D printer technology is revolutionizing spare part production. Especially in areas requiring sensitive and fast solutions such as the automotive sector, 3D spare part production offers an alternative that saves time and cost. Compared to traditional methods, spare part production with 3D printing provides a faster, flexible and environmentally friendly production process. Now, let's see the details about spare part production with 3D printing in the automotive sector.

[widget-131]

3D Spare Part Production Process

3D spare part production consists of design, file preparation, material selection and printing processes.

Digital Design: The spare part to be produced in 3D spare part production is designed in a digital environment using CAD (Computer Aided Design) programs.

File Preparation: In spare part production with 3D printing, the design is converted to STL or OBJ formats that 3D printers can read.

Material Selection: A suitable material such as plastic, metal or composite is selected according to the durability and functionality of the part.

Printing: The spare part is produced with 3D printing using the selected material.

Final Processes: If necessary, the produced part is subjected to processes such as smoothing, assembly or painting.

Quality Control: After the automotive part production with 3D printers is completed, the part is tested for compliance with the size and durability standards.

This process offers customized solutions that suit the needs of both individual users and large companies.

Spare Part Production with 3D Printing in the Automotive Sector

Spare part production with 3D printing in the automotive sector offers a perfect solution to meet the demands of the sector. Spare part production 3D technology is frequently preferred by automotive companies thanks to the following advantages:

Rapid Prototyping: Automotive part production with 3D printers allows rapid testing of design changes.

Reducing Stock Costs: Eliminates the need to keep large amounts of stock by producing 3D spare parts on demand.

Complex Designs: 3D spare part production allows easy production of complex geometric structures that are difficult to produce with traditional methods.

Lightweight Parts: Spare parts can be produced with 3D printing using lightweight materials, especially to reduce the weight of vehicles.

This method offers a great opportunity to re-produce spare parts that have been discontinued, especially for classic vehicles. Automotive part production with 3D printers provides fast and cost-effective solutions to owners of old-model vehicles, while also drawing attention with environmentally friendly production methods.

What are the Advantages of Spare Part Production with 3D Printing in the Automotive Sector?

3D spare part production offers many advantages when carried out with 3D printers:

Flexibility and Customization: Customized spare parts can be produced according to customer needs.

Cost Advantage: In the automotive sector, spare part production with 3D printing reduces initial costs by eliminating mold costs.

Time Saving: It speeds up the process from prototype production to mass production.

Environmentally Friendly Production: 3D spare part production minimizes material waste.

On-Demand Production: Spare part production with 3D printing eliminates stocking costs.

These advantages make the 3D spare part production method more attractive than traditional production processes.

In Which Areas is Spare Part Production with 3D Printing Used?

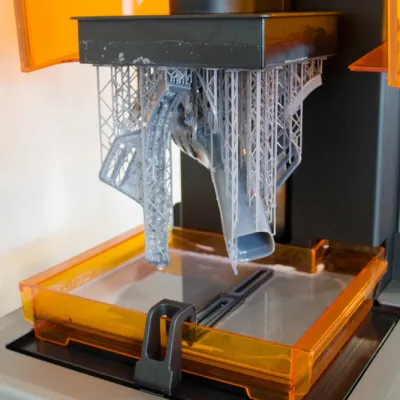

Spare part production with 3D printing is used not only in the automotive sector, but also in many different areas:

Aviation and Space: In the production of lightweight parts with high durability.

Medical Sector: Customized prosthetics and medical devices.

Electronics: Small and complex electronic parts.

Consumer Products: Personalized daily use items.

With such a wide range of applications, 3D technology in spare part production is securing its place among the production methods of the future.

Is Spare Part Production with 3D Printing Costly?

Although the initial investment costs may seem high, in the long term, serious cost advantages can be achieved when spare part production is done with 3D printers. Especially in small batch production, the elimination of mold costs and the shortening of production time offer great savings. In addition, reduced labor costs and prevention of material waste increase the cost advantages in spare part production with 3D printing.

[widget-132]

3D Spare Part Production is Valuable for the Automotive, Aerospace and Medical Sectors!

Automotive parts production and other spare parts production processes with 3D printers are at the forefront among the production technologies of the future. 3D spare parts production offers an ideal solution not only for large companies but also for individual users with the speed, cost savings and flexibility it provides. If you are looking for a modern and effective method to meet your company's spare parts needs, you can contact us about spare parts production with 3D printing. With our expert team and state-of-the-art equipment, we are ready to offer the most suitable solutions for your needs!