- Konu Başlıkları

- Innovative and Functional Productions with CNC Processing Technology

- How Does CNC Machining Work?

- CNC milling is used for the production of electronics, medical devices, aviation and automotive parts.

- Architect of Modern Manufacturing Processes: CNC Machining and 3D Printing

- Hybrid Production Model: CNC 3D Model Printing

Innovative and Functional Productions with CNC Processing Technology

Computer Numerical Control, or CNC, enables the production of precision parts through a computer-aided system. CNC processing machines, also called metal processing, use CNC turning, CNC milling, drilling and grinding machines to precisely process many raw materials from plastic to wood, from metal to composite materials. CNC processing, which has an important role together with 3D printing in modern manufacturing processes, requires expertise. Therefore, places that provide CNC processing services should be researched well; the right choices should be made in CNC processing and 3D printing services.

[widget-131]

How Does CNC Machining Work?

CNC machines, which work with pre-planned commands, move along the XY and Z axes and process materials in a computer-controlled manner, making them the desired shape. CC processing technology, which provides faster, more precise and higher quality results than manual methods, can create even complex geometries since it works with micron-level accuracy.

The most important of the processes of CNC processing machines that can process many materials such as plastic, metal, wood, composite and ceramic is CNC milling. During the metal processing process, a cutter moves on multiple axes and rotates, cutting and shaping the material. CNC milling machines can also work in complex or three-dimensional shapes. CNC milling, which is used in processes such as pocket emptying, contour processing, hole drilling and surface roughening, is faster than manual processes.

CNC milling is used for the production of electronics, medical devices, aviation and automotive parts.

Another step in metal processing technology is CNC turning. In CNC turning, a fixed cutting tool processes the rotating material. CNC turning machines, which provide high efficiency in mass production, give very good results in circular parts such as shafts, spindles and disks. Since CNC turning can also perform operations such as drilling holes, slotting and gearing, it is used in engine parts and axle production, production of machine and equipment parts, electric motors, pumps and rotary mechanisms.

Architect of Modern Manufacturing Processes: CNC Machining and 3D Printing

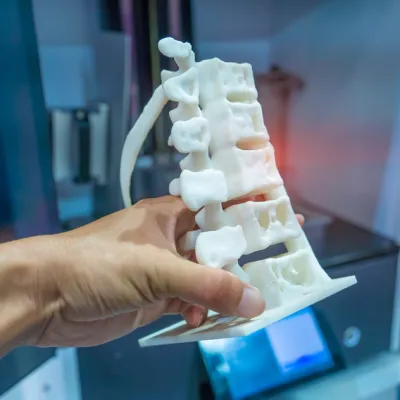

CNC 3D model printing technologies are high-precision, mutually supporting applications that are successful on complex parts in production processes. Although they offer similar functions in production, there are differences in CNC 3D model printing machines.

Metalworking CNC machines remove chips from a raw material block to shape it, that is, they work with the material removal method. In 3D printing machines, materials are added layer by layer, that is, the material addition method is used.

CNC processing, also called the metalworking system, is used in the processing of metal and hard materials; 3D printing, on the other hand, makes low-volume, complex and lightweight productions in different materials such as plastic, resin and metal. CNC processing machines extract parts from existing material, 3D printing builds models from scratch.

Another difference between the metalworking CNC 3 models is the costs. CNC can waste material in parts that require high precision, but in 3D printing, waste is prevented since only the necessary amount of material is used.

[widget-136]

Hybrid Production Model: CNC 3D Model Printing

In the hybrid production model where CNC processing and 3D printing technologies meet, CNC stands out in metalworking and parts that require durability; rapid prototyping, and 3D printing in complex and delicate details. In other words, more innovative, more functional and more efficient results are obtained by utilizing the different features and advantages of both technologies in production. In the hybrid production model, metalworking and 3D printing technologies complement each other.