- Konu Başlıkları

- Why Custom Prototypes and Small Runs Matter

- Who Benefits from Small-Batch 3D Printer Production?

- The Process of Ordering Custom 3D Printed Prototypes

- Technologies Used in Low-Volume 3D Printing

- How Flexible Are MOQs and Lead Times?

- Design Consultation for Best Results

- When to Order a Small Batch Instead of Just a Prototype

- From Prototype to Pilot Run with Erlas Global

- Summary: Your Innovation Deserves On-Demand Production Support

- Frequently Asked Questions

Today’s innovation-driven economy demands flexibility, speed, and precision—especially for startups, R&D departments, and niche-market companies. When mass production is either too soon or too excessive, the ability to order custom 3D printer prototypes or request small batch runs offers a critical advantage.

This guide explains how customized 3D printing helps you get from concept to market faster, reduce risk, and align your production scale with your actual business needs. Whether you’re developing a new product or testing market response, small-batch additive manufacturing provides the scalability and responsiveness modern teams need.

[widget-131]

Why Custom Prototypes and Small Runs Matter

Startups and innovation teams often need to test ideas quickly. Creating one prototype is rarely enough—multiple iterations are typically required to optimize fit, function, and user experience. And once the design is finalized, producing a small batch helps validate performance in real-world conditions or deliver early units to clients or investors.

Here’s why low-volume runs using 3D printing are essential:

- Lower financial risk compared to traditional tooling

- Faster turnaround to test, revise, and launch

- Design flexibility with no minimum order pressure

- On-demand production aligned with your development cycle

Who Benefits from Small-Batch 3D Printer Production?

Several sectors and business types benefit directly from ordering small-volume custom parts:

- Startups refining MVPs (minimum viable products)

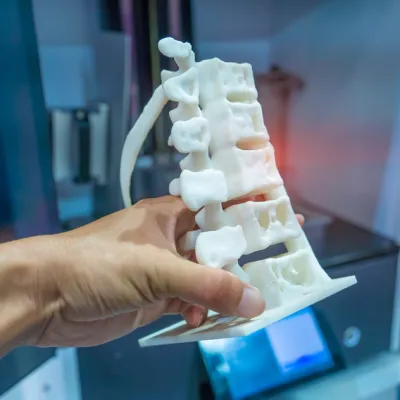

- Medical device developers running clinical trials

- Consumer electronics brands doing pilot releases

- Fashion tech & wearables needing unique enclosures

- Architects producing presentation models

For these users, the ability to order custom 3D printer prototypes and not overcommit resources is mission-critical.

The Process of Ordering Custom 3D Printed Prototypes

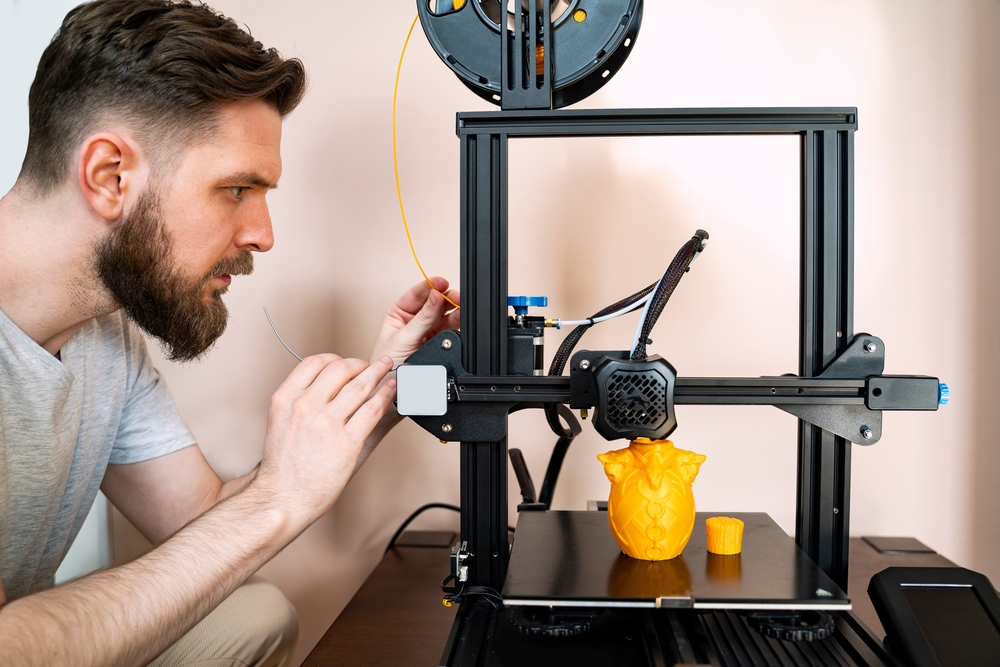

At Erlas Global, the custom prototyping and low-volume production process is fast, streamlined, and highly consultative. The journey begins with understanding your functional and aesthetic requirements. Clients can either upload ready-made CAD files or request support in design refinement.

The process includes:

- Design review and consultation

- Material recommendation based on intended use

- 3D printing method selection (FDM, SLA, SLS, etc.)

- Prototype production with optional post-processing

- Iteration or small-batch replication

- Quality assurance and delivery scheduling

A startup developing a wearable health monitor, for instance, used Erlas Global’s expertise in 3D prototyope production to finalize its enclosure in just four iterations—going from idea to client-ready units within weeks.

Technologies Used in Low-Volume 3D Printing

The choice of 3D printing method is essential to the success of a custom prototype or limited production run. Depending on geometry, mechanical stress, and surface finish requirements, different technologies offer different advantages:

- FDM (Fused Deposition Modeling) for fast, cost-efficient prototypes

- SLA (Stereolithography) for smooth, high-resolution surfaces

- SLS (Selective Laser Sintering) for durable, complex parts

- Metal 3D printing for end-use, functional components

Erlas Global’s 3D printer production division ensures that each project is matched with the right method and material.

How Flexible Are MOQs and Lead Times?

Minimum order quantities (MOQs) are often a barrier for emerging brands. With traditional manufacturers, low-volume orders may not be accepted—or are priced punitively.

Erlas Global takes a different approach. Their 3D printing service offers:

- No fixed MOQ — order 1 or 100 depending on your needs

- Expedited delivery options — as fast as 24–72 hours for urgent prototypes

- Batch repeatability — produce consistent units with archived print profiles

- Adaptable volume scaling — transition from prototype to pilot run smoothly

In one case, a client in the cosmetic packaging industry needed just 35 customized caps for a focus group. Rather than investing in injection molds, they used 3D printing service to produce detailed samples that mimicked final product appearance.

Design Consultation for Best Results

Designing for 3D printing differs from traditional manufacturing. That’s why Erlas Global offers hands-on consultation with every custom prototype or small run order. Clients benefit from:

- Design for Additive Manufacturing (DfAM) guidance

- Support optimization to reduce post-processing

- Wall thickness and tolerance calibration

- Material and surface finish suggestions

This collaborative approach eliminates reprints, enhances functional performance, and ensures each piece is production-ready.

When to Order a Small Batch Instead of Just a Prototype

A prototype answers the question: Does this work?

A small batch answers: Can this scale?

Consider ordering a small batch when:

- You need user feedback before scaling

- Investors require functional samples

- You want to test multiple materials or colors

- Your internal team needs field testing units

- You're planning a limited edition product release

3D printing allows these small batches to be affordable, fast, and detailed—making them ideal for strategic decision points.

From Prototype to Pilot Run with Erlas Global

Erlas Global bridges the gap between prototyping and scaled production. With clear communication, technical expertise, and in-house machinery, they’re equipped to help your team make confident product decisions and scale efficiently.

Clients appreciate their ability to store and reuse models, track iterations, and adapt materials per run—all while ensuring precision and consistency.

Summary: Your Innovation Deserves On-Demand Production Support

In a world where speed and flexibility define success, being able to order custom 3D printer prototypes and run small batch productions is no longer a luxury—it’s a necessity. This model gives you full control over timelines, budgets, and outcomes, allowing you to innovate confidently and launch products faster.

Erlas Global offers everything a startup, R&D team, or specialized brand needs to turn an idea into a tangible, testable, and deliverable product. Through expert consultation, advanced technology, and a commitment to flexibility, your vision is always just a few prints away from reality.

[widget-136]

Frequently Asked Questions

Can I order just one prototype or part?

Yes, Erlas Global supports orders as small as a single unit with no MOQ restrictions.

How quickly can I receive my custom prototype?

Depending on complexity and volume, turnaround can be as fast as 1–3 business days.

Do I need to provide a finished 3D model?

No. You can submit rough designs, and their team will assist with optimization.

Is post-processing included?

Standard finishing is included, with options for advanced surface treatment available.

Can small batches be repeated later?

Absolutely. Erlas Global archives each design for consistent reprints and scaling.