- Konu Başlıkları

- Building an Efficient 3D Printing Supply Chain

- Strategic Material Sourcing

- Optimizing Global Logistics

- Navigating International Compliance

- Proactive Risk Mitigation

- Case Study: Erlas Global’s Supply Chain Excellence

- Sustainability in Global 3D Printing

- Actionable Strategies for Procurement Managers

- Frequently Asked Questions (FAQs)

- What are the main challenges in global 3D printer production?

- How can businesses optimize their 3D printing supply chain?

- Why prioritize sustainability in 3D printing supply chains?

- Streamlining Your 3D Printing Future

The 3D printing industry drives innovation across sectors, but its efficiency depends on robust global 3D printer production strategies. Procurement managers and supply chain professionals face the challenge of sourcing high-quality materials and managing complex international logistics to deliver precision components. This guide provides actionable solutions for optimizing sourcing and supply chains, drawing on the 40-year expertise of Erlas Global. From strategic partnerships to risk mitigation, we explore how to streamline global 3D printing operations.

Building an Efficient 3D Printing Supply Chain

A seamless 3D printing supply chain integrates material sourcing, logistics, and compliance to meet the demands of international businesses. Each element requires careful planning to ensure cost-effectiveness and reliability.

[widget-131]

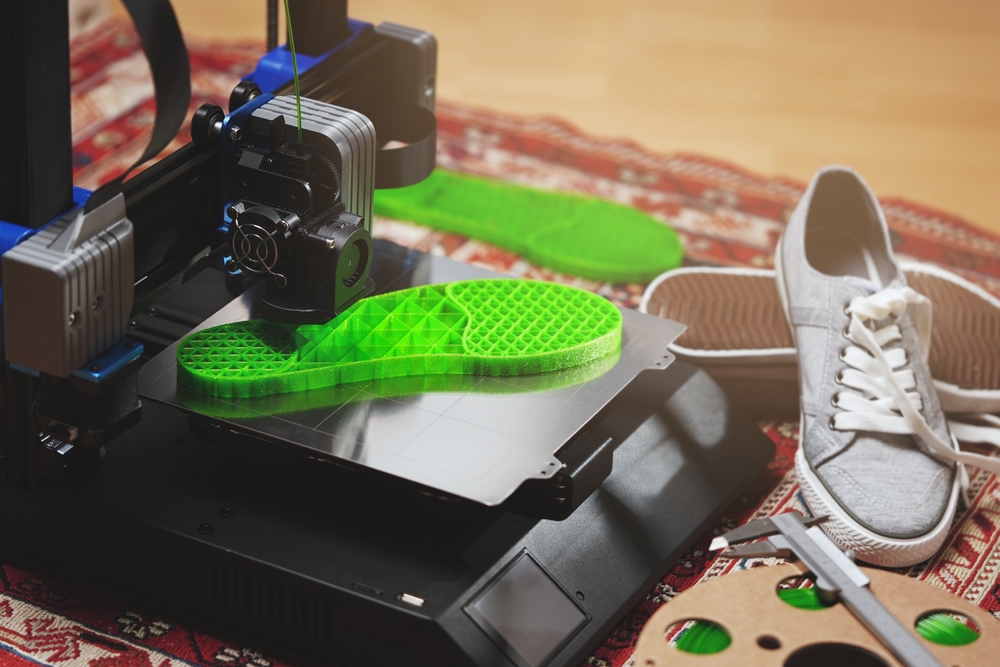

Strategic Material Sourcing

Effective 3D printing sourcing starts with securing high-quality materials like thermoplastics (ABS, PLA), metals (aluminum, stainless steel), and composites. Erlas Global collaborates with certified suppliers across Europe and Asia to ensure ISO-compliant materials. This approach guarantees filament consistency, vital for applications like medical devices and automotive parts.

Their expertise in material selection for advanced manufacturing reduces defects and enhances production quality, setting a benchmark for global operations.

Optimizing Global Logistics

Logistics optimization is critical for coordinating production across regions. Erlas Global’s network of logistics partners streamlines shipping, minimizes lead times, and navigates customs complexities. Their European-standard facilities enable just-in-time delivery, reducing inventory costs while maintaining production schedules.

Navigating International Compliance

Adhering to international compliance standards like REACH, RoHS, and regional regulations is a cornerstone of global 3D printing. Erlas Global’s ISO-certified processes ensure compliance, minimizing regulatory risks. Their experience in prototype production for international markets showcases their ability to meet diverse standards seamlessly.

Proactive Risk Mitigation

Supply chain disruptions, from material shortages to geopolitical challenges, can derail production. Erlas Global employs risk mitigation strategies like diversified supplier networks and predictive analytics to anticipate issues. A case study from their automotive work highlights how they sourced alternative filaments during a supply shortage, ensuring uninterrupted production.

This adaptability underpins their tailored 3D printing solutions, which meet client-specific needs across industries.

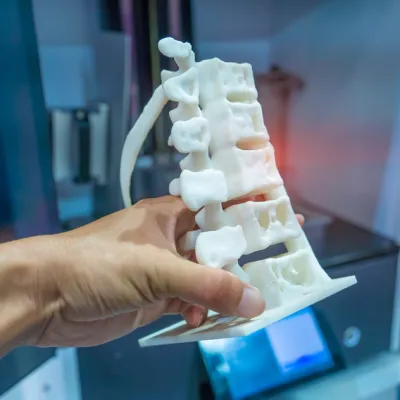

Case Study: Erlas Global’s Supply Chain Excellence

Erlas Global’s expertise was evident in a project for a healthcare client needing 3D-printed surgical models. By sourcing biocompatible materials and coordinating logistics across three continents, they delivered 500 units in under two weeks. The client praised their “flawless execution and strict adherence to regulatory standards,” underscoring their reliability in high-stakes scenarios.

Sustainability in Global 3D Printing

Sustainability is reshaping supply chain management. Erlas Global integrates recycled materials and energy-efficient processes to reduce environmental impact. Their partnerships with eco-conscious suppliers align with global sustainability goals, appealing to businesses prioritizing green manufacturing.

Actionable Strategies for Procurement Managers

Optimizing a 3D printing supply chain demands strategic foresight. Key strategies include:

- Diversify Suppliers: Partner with multiple vendors to reduce dependency risks.

- Use Predictive Analytics: Forecast demand and disruptions with data-driven tools.

- Ensure Compliance: Verify suppliers meet ISO, REACH, and other standards.

Frequently Asked Questions (FAQs)

What are the main challenges in global 3D printer production?

Key challenges include sourcing consistent materials, coordinating global logistics, and ensuring regulatory compliance. Experts like Erlas Global address these with strategic solutions.

How can businesses optimize their 3D printing supply chain?

Prioritize diversified sourcing, logistics partnerships, and predictive analytics to boost efficiency and cut costs.

Why prioritize sustainability in 3D printing supply chains?

Sustainable practices reduce environmental impact and align with corporate responsibility, attracting eco-conscious clients.

[widget-136]

Streamlining Your 3D Printing Future

Effective global 3D printer production hinges on strategic sourcing, streamlined logistics, and proactive risk management. Erlas Global’s 40-year expertise, ISO-compliant processes, and sustainable practices position them as a trusted partner for procurement managers and international businesses. Their proven ability to deliver high-quality components across industries ensures efficiency and reliability. Ready to optimize your 3D printing supply chain? Partner with Erlas Global to transform your manufacturing vision into reality.