- Konu Başlıkları

- Key Factors Influencing 3D Printer Production Cost

- 1. Technology Type: The Foundation of Cost

- 2. Material Choice: More Than Just the Raw Price

- 3. Part Geometry and Complexity: Design Dictates Price

- 4. Post-Processing Requirements: The Hidden Costs

- Scalability and Volume: Optimizing for Your Project Size

- 1. One-Off Prototypes vs. Batch Production

- 2. The Role of Service Providers: Expertise vs. DIY

- Cost Optimization Strategies for Your 3D Printing Project

- The Erlas Global Advantage: Transparency, Quality, and Value

- Long-Term Value: Beyond the Initial Price Tag

- Frequently Asked Questions About 3D Printing Costs

- Conclusion: Mastering Your 3D Printing Budget

In today's competitive landscape, businesses and startups constantly seek innovative solutions to bring their ideas to life, and 3D printing stands out as a transformative technology. However, a common question often arises: "What is the true 3D printer production cost?" Understanding the financial implications of additive manufacturing is crucial for effective budgeting, strategic planning, and ensuring a healthy return on investment (ROI). This comprehensive guide aims to demystify the various factors influencing the cost of 3D printer production, providing transparent insights to help you make informed decisions.

From material choices to post-processing requirements, every aspect plays a role in the final expenditure. We'll break down these elements, discuss how different production scales impact pricing, and offer actionable strategies to optimize your budget without compromising on quality or performance. Our goal is to equip budget-conscious innovators with the knowledge needed to navigate the complexities of 3D printing costs and leverage this technology to its full potential.

[widget-131]

Key Factors Influencing 3D Printer Production Cost

The cost of 3D printer production is not a single fixed number but rather a dynamic calculation influenced by several interconnected variables. A thorough understanding of these elements is the first step towards accurate rapid prototyping budgeting and effective project management.

1. Technology Type: The Foundation of Cost

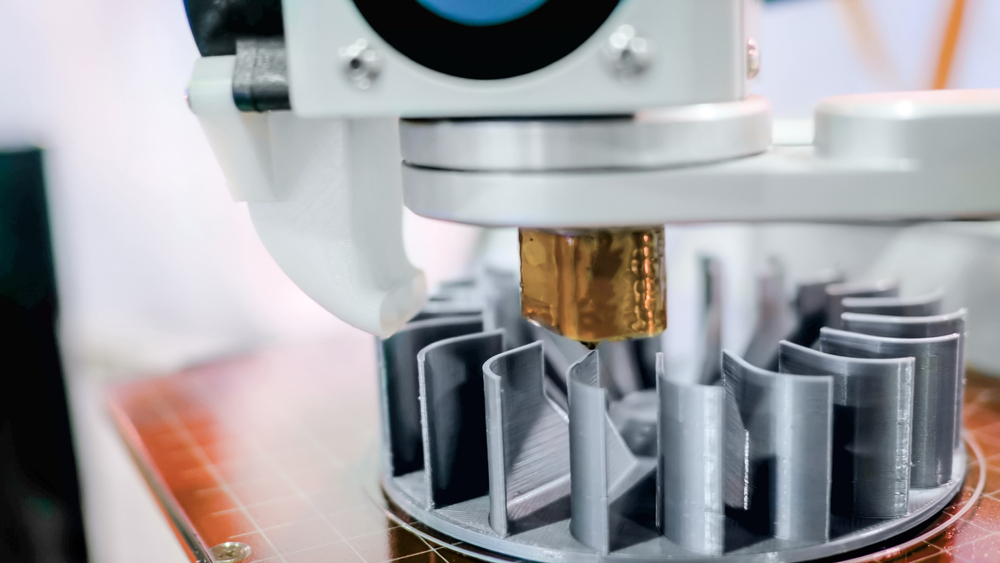

Different 3D printing technologies operate on varying principles, each carrying its own cost structure in terms of equipment, materials, and operational complexity. Here are the primary types and their general cost implications:

- Fused Deposition Modeling (FDM): Often the most affordable option, FDM uses thermoplastic filaments. It's suitable for basic prototypes and functional parts where intricate detail and super-smooth surfaces are not paramount.

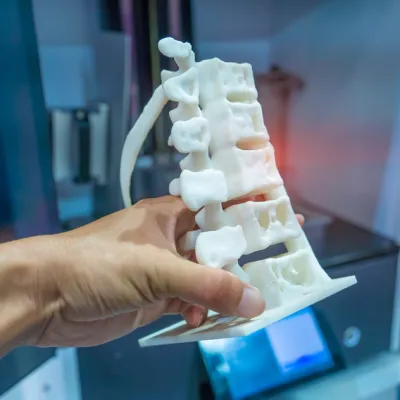

- Stereolithography (SLA) & Digital Light Processing (DLP): These resin-based technologies offer higher resolution and smoother finishes, ideal for detailed models and aesthetic prototypes. The resins are typically more expensive than FDM filaments, affecting the material expenditure.

- Selective Laser Sintering (SLS): Using powdered polymers, SLS produces strong, functional parts with excellent mechanical properties and no need for support structures. While versatile, the machines and materials are generally pricier than FDM or SLA.

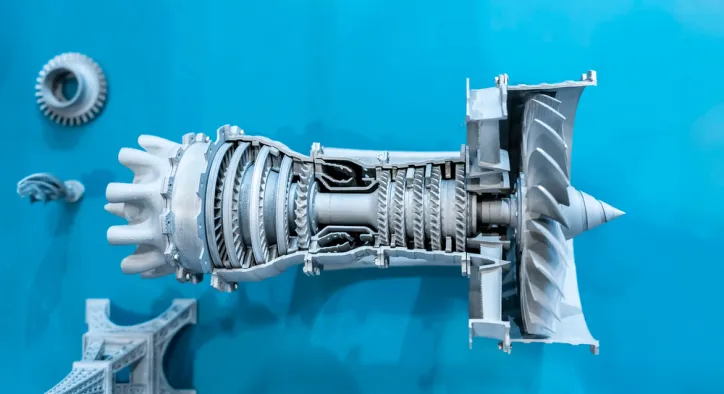

- Metal 3D Printing (e.g., SLM, DMLS, Binder Jetting): The most expensive segment, metal 3D printing yields high-strength, high-performance parts. Costs are driven by expensive metal powders, complex machinery, and significant post-processing fees. This is often chosen for highly specialized, end-use industrial parts.

The choice of technology directly dictates the base price per part and sets expectations for material and finishing costs.

2. Material Choice: More Than Just the Raw Price

The type and quantity of material used are significant drivers of overall 3D printer production cost. Beyond the per-kilogram or per-liter price of the material itself, factors like material availability, specific handling requirements, and waste generated during the printing process contribute to the total. For example:

- Standard Plastics (PLA, ABS, PETG): Generally cost-effective and widely available.

- Engineering-Grade Polymers (Nylon, PC, PEEK): Offer enhanced mechanical properties but come at a higher price point.

- Resins: Vary widely in price based on properties (e.g., standard, tough, flexible, dental, castable).

- Metal Powders (Stainless Steel, Aluminum, Titanium): These are by far the most expensive materials, with costs often reflecting their performance characteristics and the intricate processes required for their use.

Careful consideration of the material’s properties versus the part's functional requirements can lead to substantial savings. Sometimes, a slightly more expensive material upfront can reduce post-processing fees or increase part lifespan, leading to better long-term ROI.

3. Part Geometry and Complexity: Design Dictates Price

The design of your part plays a crucial role in its production cost. Complex geometries, intricate internal structures, and thin walls often require more material (especially for support structures), longer print times, and more intensive post-processing. Features that increase cost include:

- Volume and Dimensions: Larger parts naturally consume more material and take longer to print.

- Surface Area: Directly impacts print time and the amount of material.

- Support Structures: Required for overhangs and complex features in many technologies (FDM, SLA). Removing these adds to post-processing fees and labor time.

- Wall Thickness: Very thin walls can increase print time and may lead to higher failure rates, requiring re-prints.

- Part Density/Infill: Solid parts use more material and take longer than hollow or low-infill parts.

Utilizing Design for Additive Manufacturing (DfAM) principles can significantly optimize geometry for cost-effectiveness and printability. A knowledgeable 3D printer production service can provide valuable feedback on design adjustments to reduce costs.

4. Post-Processing Requirements: The Hidden Costs

After a part is printed, it often requires various post-processing steps to achieve the desired finish, accuracy, and functionality. These steps can significantly add to the overall 3D printer production cost.

- Support Removal: Manual or automated removal of support structures.

- Curing (for resin prints): UV curing for SLA/DLP parts.

- Cleaning: Removing excess powder (SLS) or uncured resin.

- Surface Finishing: Sanding, polishing, vapor smoothing, painting, dyeing, or coating for aesthetic or functional purposes.

- Assembly: If the final product consists of multiple printed or assembled components.

- Heat Treatment: For metal parts to improve mechanical properties.

Each of these steps requires labor, specialized equipment, and sometimes additional materials, directly impacting the final custom part manufacturing price. Transparent communication with your service provider about desired finishes is crucial to avoid unexpected costs.

Scalability and Volume: Optimizing for Your Project Size

The quantity of parts you need is a major determinant of your total 3D printing cost. While 3D printing excels at low-volume and one-off production, understanding its scalability considerations is key.

1. One-Off Prototypes vs. Batch Production

For single prototypes, 3D printing is often more cost-effective than traditional manufacturing methods like injection molding, which require expensive tooling. However, as volume increases, the unit cost for 3D printing may not decrease as sharply as with conventional methods.

- One-Off / Low Volume: 3D printing offers speed and design freedom. The cost per unit is relatively high due to fixed setup times and material waste that isn't amortized over many units. This is where 3D prototype production shines for initial design validation.

- Batch Production / Medium Volume: Some 3D printing technologies (e.g., SLS) are more efficient for batch production, allowing many parts to be printed in a single build chamber. This reduces the per-part cost significantly compared to printing individual parts.

- Mass Production: For very high volumes, traditional manufacturing often becomes more cost-efficient due to economies of scale, despite the initial tooling costs. However, 3D printing is increasingly used for bridge manufacturing or customizable mass production.

A good service provider will help you identify the most cost-effective production method based on your required volume and project lifecycle.

2. The Role of Service Providers: Expertise vs. DIY

While consumer-grade 3D printers are accessible, industrial-grade 3D printer production involves complex machinery, specialized materials, and a high degree of expertise. Deciding between in-house production and outsourcing to a professional 3D printing service is another crucial cost consideration.

- In-house Production: Requires significant upfront investment in machinery, materials, software, and skilled personnel (training, salaries). Ongoing costs include maintenance, utilities, and material replenishment.

- Outsourcing to a Service Provider: Eliminates upfront capital expenditure and maintenance costs. You pay per part or project, gaining access to a wide range of technologies, materials, and expert advice without the operational burden. This is often the more cost-effective 3D printing solution for startups and businesses with fluctuating needs.

Professional services, like those offered by Erlas Global, provide not just the printing capacity but also critical insights on design optimization, material selection, and post-processing, which can prevent costly errors and improve overall efficiency.

Cost Optimization Strategies for Your 3D Printing Project

Managing the 3D printer production cost effectively requires a strategic approach. Here are practical tips to keep your budget in check while achieving your desired outcomes:

1. Optimize Design for Additive Manufacturing (DfAM): Collaborate with your design team or service provider to simplify geometries, reduce material usage, minimize support structures, and consolidate parts. Even minor design tweaks can lead to significant savings in material and print time.

2. Choose the Right Technology and Material: Don’t over-engineer your part. If a simple FDM print with PLA suffices for a visual prototype, there’s no need for an expensive metal print. Match the technology and material to the part’s actual functional and aesthetic requirements.

3. Iterate Efficiently: Use early-stage, cheaper prototypes for quick validation, then move to more precise and expensive methods for later iterations. This iterative approach minimizes risk and allows for critical feedback loops before significant additive manufacturing investments are made.

4. Consider Infill and Shell Thickness: For non-functional parts, reducing infill density and shell thickness can dramatically cut down on material consumption and print time, directly lowering the material expenditure.

5. Batch Parts (If Applicable): If you need multiple small parts, combine them into a single print job. This can reduce setup costs and maximize the efficiency of the build volume, leading to lower per-unit volume production pricing.

6. Define Post-Processing Needs Clearly: Be precise about the level of finish required. Over-specifying finishes can add unnecessary labor and cost. For example, if a part is hidden, extensive polishing might not be necessary.

7. Leverage Expert Consultation: A reputable 3D printing service provider can offer invaluable guidance. Their experience allows them to recommend the most cost-efficient approaches, identify potential design flaws, and optimize your project for both quality and budget. This expertise minimizes trial-and-error, saving time and money.

The Erlas Global Advantage: Transparency, Quality, and Value

At Erlas Global, we understand that managing 3D printer production cost is a primary concern for businesses, especially for innovative startups. Our approach is built on transparency, offering detailed breakdowns of all cost factors, ensuring you know exactly where your budget is allocated.

We pride ourselves on providing high-quality prints that meet stringent specifications while actively seeking ways to optimize your rapid prototyping budgeting. Our expert team guides you through material selection, design optimization for cost-efficiency, and smart post-processing choices. By leveraging industrial-grade printers and a deep understanding of additive manufacturing, Erlas Global delivers not just parts, but solutions that offer genuine value and superior ROI.

We believe that access to cutting-edge 3D printing shouldn't be cost-prohibitive. Our commitment is to partner with you, ensuring your projects are executed efficiently, within budget, and with the highest standards of quality. This dedication to excellence and client success truly differentiates our 3D printing service.

Long-Term Value: Beyond the Initial Price Tag

When evaluating the 3D printer production cost, it’s crucial to look beyond the immediate expenditure and consider the long-term value. A seemingly higher initial investment in a quality print or service can translate into significant savings down the line by:

- Reducing Design Iterations: High-fidelity prototypes minimize the need for multiple design changes, accelerating time to market.

- Enhancing Product Performance: Quality parts lead to more reliable and higher-performing final products, reducing warranty claims or recalls.

- Improving User Experience: Ergonomically sound and aesthetically pleasing prototypes can lead to better market acceptance and higher sales.

- Minimizing Material Waste: Optimized processes and expert handling reduce wasted material, lowering material expenditure and environmental impact.

- Ensuring Durability and Longevity: Investing in appropriate materials and post-processing ensures the parts withstand their intended use, reducing replacement costs.

Ultimately, a strategic investment in 3D printer production cost for quality and precision pays dividends by optimizing the entire product development lifecycle and enhancing your final product's success.

[widget-136]

Frequently Asked Questions About 3D Printing Costs

How much does 3D printing a custom part usually cost?

The cost varies significantly based on factors like part size, complexity, chosen material, technology, and post-processing. A small, simple plastic part might cost a few dollars, while a complex metal component could run into hundreds or thousands of dollars. Always request a detailed quote based on your specific 3D model.

Is it cheaper to buy my own 3D printer or use a service?

For occasional projects or hobby use, buying a basic FDM printer can be cost-effective. However, for professional-grade parts, diverse material needs, large volumes, or complex designs, using a professional service is generally more economical. They absorb the costs of expensive equipment, maintenance, and expert labor, offering you access to high-end capabilities without the upfront additive manufacturing investments.

How can I get the best price for my 3D printing project?

To optimize your 3D printer production cost, focus on design efficiency (DfAM), choose the most suitable and not over-specified material/technology, clearly define your post-processing needs, and consider batching parts if possible. Engaging a transparent and expert service provider early in the design phase is key.

Do material costs make up the largest portion of the total 3D printing cost?

Material costs are a significant factor, especially for large parts or expensive materials like metal powders. However, for complex parts, the labor involved in printing (machine time), support removal, and extensive post-processing can often constitute a larger portion of the total production pricing.

Can 3D printing reduce overall production costs in the long run?

Yes, absolutely. While initial per-part costs might seem higher than mass manufacturing, 3D printing significantly reduces tooling costs, accelerates design cycles, allows for rapid iterations, and minimizes waste. These factors can lead to substantial overall savings in product development time and market entry, ultimately improving 3D printing ROI.

Conclusion: Mastering Your 3D Printing Budget

Understanding the 3D printer production cost is essential for any business looking to harness the power of additive manufacturing. It's a nuanced calculation, influenced by technology, materials, design complexity, post-processing, and volume. By taking a transparent and informed approach, you can effectively budget your projects, optimize costs, and unlock the immense potential of 3D printing for your innovations.

Choosing a partner like Erlas Global, who prioritizes clarity, quality, and strategic value, ensures that your investment translates into superior prototypes and functional parts. Our expertise helps you navigate the cost landscape, providing you with the precision, reliability, and efficiency needed to bring your vision to life. Don't let cost uncertainties hold you back; empower your projects with smart, informed 3D printing solutions.