- Konu Başlıkları

- All Details About 3D Prototype Production… What Does a Prototype Mean?

- What is a Prototype and How is it Made?

- How is the Prototyping Process Made?

- The Initial Design Phase and Concept Development

- Modeling Phase of Prototype Design

- Prototype Production

- Testing and Evaluation

- Improvement and Reaching the Final Design

- Modern Prototyping Methods with 3D Prototyping Production

- Erlas Global is Always With You!

All Details About 3D Prototype Production… What Does a Prototype Mean?

A prototype can be defined as the first example of a product or design. This is the first stage of turning an idea or concept into reality. Prototypes are the first models or samples made to test the operation, design and functionality of a product. Prototypes, which play an important role in the design process, usually provide important information about how the final product will be. The prototyping process is a critical step to ensure that the product is designed and developed correctly.

So, what is a prototype and how is it made? Now, let's take a detailed look at the concept of prototype, the production process of prototypes, the methods used and how this process has become more efficient with modern technologies such as 3D prototype production.

[widget-130]

What is a Prototype and How is it Made?

The answer to the question of what is a prototype and how is it made can be explained as the first example of a certain product or design. A prototype enables an idea to become concrete. Designers and engineers test their designs by making prototypes before turning their ideas into reality. This process is very important for evaluating the functionality, aesthetic features and manufacturability of the design. The question of what is a prototype and how is it made is also a question that includes the challenges and opportunities encountered in the product development process.

A prototype can be a simple mock-up or a fully functional model. Prototypes are usually made in the early stages of the design process, usually for testing and trial purposes. In addition, prototypes offer designers and engineers the opportunity to test the product's cost, production process and user experience.

How is the Prototyping Process Made?

What does a prototype mean? The prototyping process consists of a series of steps starting from the early stages of design. This process is of great importance for designers, engineers and manufacturers. The steps to be followed to create a prototype may vary depending on the technology used, the complexity of the design and the targeted product.

The Initial Design Phase and Concept Development

The prototyping process begins with the initial creation of ideas and the transfer of these ideas to design. Designers determine what the product is for, what features it will have, and what problems it should solve. This phase takes shape with the creation of initial design sketches and drawings. Ideas are usually transferred to a digital environment using computer-aided design (CAD) software.

Modeling Phase of Prototype Design

After determining a design idea, digital models are created for prototype production. This phase involves detailed modeling of a physical version of the product in a digital environment before it is built. The digital model includes the dimensions, shapes and functional features of the product. This modeling process helps to detect and correct design errors in advance.

Prototype Production

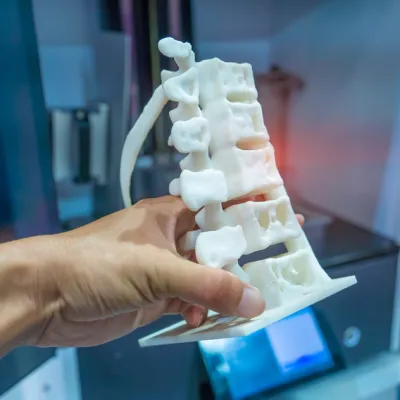

What is a prototype and how is it made? The most important phase of the prototype question is the physical production of the prototype. 3D prototype production comes into play at this stage. With traditional methods, prototypes were usually produced by hand or casting methods. However, today, 3D printing technology performs this process much faster, at lower cost and with greater precision.

3D prototype production enables a design to transform into a real object by adding material layer by layer. This technology is widely used, especially in rapid prototyping processes. 3D prototype production significantly shortens production times and allows for more flexible design changes.

Testing and Evaluation

After the prototype is produced, the functionality of the design is tested. The prototype is examined, tested and its performance is evaluated by engineers and designers. At this stage, the product is subjected to various tests to reveal design errors and deficiencies. User feedback can also be received at this stage. The most important function of the prototype in the design process is to detect possible errors at an early stage.

Improvement and Reaching the Final Design

After the prototype is tested, necessary improvements are made to the design. Another important answer to the question of what a prototype means is that prototypes are used to correct errors. After the negative aspects of the prototype are determined, the necessary changes are made to the design and this process is repeated. Each prototype allows the creation of a version of the product closer to its final design.

Modern Prototyping Methods with 3D Prototyping Production

In recent years, 3D prototype production has begun to replace traditional prototyping methods. This technology allows the design to quickly become a prototype. 3D prototype production offers great advantages, especially in terms of rapid testing of prototypes and obtaining accurate results. 3D printing both reduces costs and allows designs to be more complex and original.

With 3D prototype production, production processes become much shorter and more cost-effective compared to traditional prototyping methods. In addition, creating the shape and design of the product in a digital environment makes the design process more efficient and flexible.

[widget-137]

Erlas Global is Always With You!

The question of what a prototype is and how it is made is one of the most important stages in product design and development processes. Prototypes enable designers to turn their ideas into reality and help them realize deficiencies before the product reaches its final form. Modern technologies such as 3D prototype production make the prototyping process more efficient while also reducing costs and production times. In this way, designers, engineers and manufacturers can produce higher quality and error-free products.

Prototype production is a process of great importance in every sector. Whether it is automotive, medical or consumer electronics, prototypes in every field are elements that directly affect the success of the product. The clearest answer to questions such as what is a prototype and how is it made, what does a prototype mean, and prototyping is that the first version of a design should be made.