- Konu Başlıkları

- Overview of 3D Printing Materials

- Polymers: The Foundation of 3D Printing

- Metals: Precision and Durability

- Composites and Advanced Materials

- Factors Influencing Material Selection

- Testing and Validation for Material Performance

- Sustainability in 3D Printing Materials

- Practical Tips for Optimizing Material Selection

- Frequently Asked Questions (FAQs)

- What are the most common materials used in 3D printing, and how do they differ?

- How can I choose the right material for my 3D printing project?

- Are sustainable materials a viable option for 3D printing projects?

- Mastering Material Selection for 3D Printing Excellence

Selecting the right materials for 3D printing is a pivotal decision that shapes the performance, durability, and cost-effectiveness of manufactured components. Understanding 3D printer production materials empowers engineers and manufacturers to align their choices with project requirements, whether for prototyping or large-scale production. This comprehensive guide explores the key materials used in 3D printing, their technical properties, applications across industries, and factors influencing selection. By delving into polymers, metals, composites, and sustainable options, this resource equips decision-makers with the knowledge to optimize their manufacturing processes.

[widget-131]

Overview of 3D Printing Materials

3D printing, or additive manufacturing, relies on a diverse array of materials tailored to specific applications. From flexible polymers to high-strength metals, each material category offers unique advantages that cater to varying mechanical, environmental, and budgetary needs. This section outlines the primary material types, their properties, and their roles in modern manufacturing.

Polymers: The Foundation of 3D Printing

Polymers in 3D printing are the most accessible and widely used materials due to their versatility, cost-effectiveness, and ease of printing. Common polymers include Acrylonitrile Butadiene Styrene (ABS), Polylactic Acid (PLA), and Thermoplastic Polyurethane (TPU). ABS is prized for its durability and heat resistance, making it ideal for functional parts in automotive and consumer electronics. PLA, derived from renewable sources like corn starch, is biodegradable and favored for prototyping and eco-conscious applications. TPU, with its elasticity, is perfect for flexible components like wearable devices or gaskets.

Selecting the right polymer can significantly impact production outcomes, as explored in this guide on advanced manufacturing techniques. For instance, ABS requires precise temperature control to prevent warping, while PLA’s ease of use makes it a go-to for rapid prototyping.

- ABS: High impact resistance, suitable for functional parts in harsh environments.

- PLA: Biodegradable, easy to print, ideal for non-functional prototypes.

- TPU: Flexible, abrasion-resistant, used for soft or elastic components.

Metals: Precision and Durability

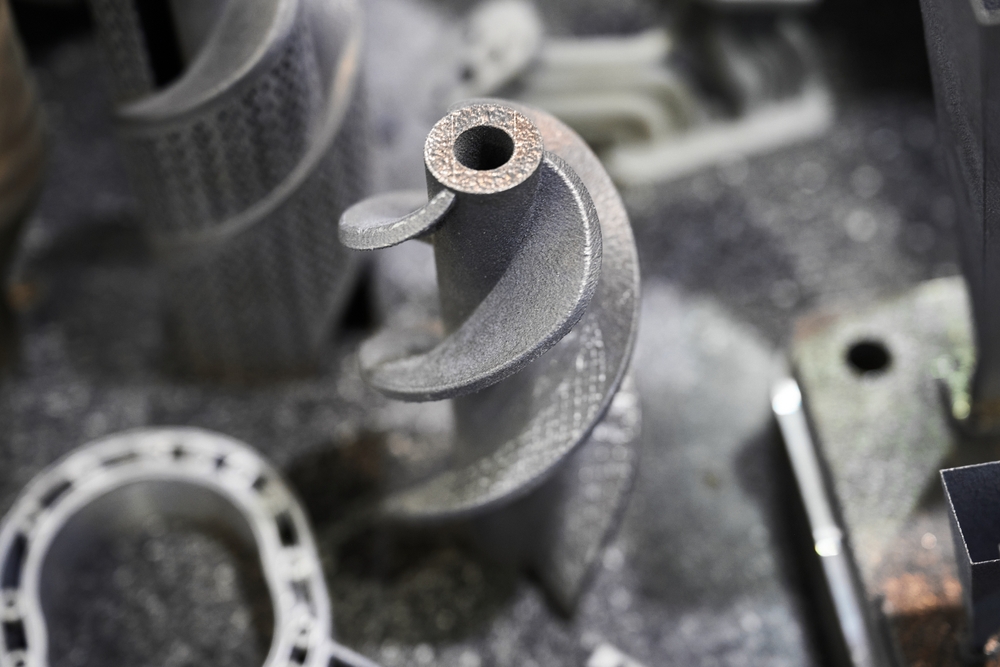

Metals for 3D printing, such as stainless steel, titanium, and aluminum, are essential for applications requiring superior strength and precision. Technologies like Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS) enable the production of complex metal parts for aerospace, medical, and automotive industries. Stainless steel offers corrosion resistance, titanium provides an exceptional strength-to-weight ratio, and aluminum is lightweight yet durable, making it ideal for structural components.

Metal 3D printing demands advanced equipment and expertise, but the results are transformative. For example, titanium implants in medical applications benefit from biocompatibility and precision, while aluminum parts in aerospace reduce weight without sacrificing strength. Learn more about optimizing production costs with metal printing to balance performance and budget.

Composites and Advanced Materials

Additive manufacturing materials like carbon fiber-reinforced polymers and ceramics are gaining prominence for their specialized properties. Carbon fiber composites combine lightweight design with high strength, making them ideal for aerospace components like turbine blades or automotive chassis parts. Ceramics, with their heat and wear resistance, are used in high-temperature environments, such as jet engine components or dental implants.

These advanced materials require precise printing techniques and often involve higher costs, but their performance justifies the investment in niche applications. For projects requiring tailored solutions, exploring custom prototype production can help validate material choices before scaling up.

Factors Influencing Material Selection

Choosing the optimal material for 3D printing involves evaluating multiple factors to ensure alignment with project goals. These include:

- Mechanical Properties: Strength, flexibility, and durability must match the component’s intended use. For example, a medical implant requires biocompatibility, while an automotive part needs impact resistance.

- Cost Considerations: Polymers like PLA are budget-friendly, while metals like titanium are costlier but offer superior performance.

- Environmental Factors: Exposure to heat, chemicals, or UV light influences material choice. For outdoor applications, UV-resistant ABS is preferable to PLA.

- Sustainability: Biodegradable materials like PLA or recycled metals support eco-friendly manufacturing, aligning with global sustainability goals.

- Printability: Some materials, like TPU, require specialized printers, while others, like PLA, are compatible with standard FDM machines.

Testing and Validation for Material Performance

Before committing to large-scale production, testing material performance is critical. Techniques like tensile strength testing, thermal analysis, and environmental stress testing ensure that chosen materials meet project requirements. For instance, ASTM standards (e.g., ASTM F2792 for additive manufacturing) provide guidelines for evaluating material properties. Prototyping allows engineers to validate material choices, reducing risks of failure in final production.

A case study from the automotive industry illustrates this: a manufacturer tested carbon fiber-reinforced polymers against standard ABS for a chassis component. The composite’s superior strength-to-weight ratio justified its higher cost, leading to a 20% weight reduction and improved fuel efficiency.

Sustainability in 3D Printing Materials

Sustainability is increasingly shaping material choices in 3D printing. Sustainable 3D printing materials, such as biodegradable PLA and recycled metals, reduce environmental impact while maintaining performance. Recycled ABS, for example, offers similar durability to virgin material but lowers carbon footprints. Some manufacturers are also exploring bio-based resins and reclaimed composites to align with circular economy principles.

Adopting sustainable materials not only benefits the environment but also appeals to eco-conscious clients and regulators. For instance, industries like consumer goods are prioritizing PLA for packaging prototypes to meet sustainability targets.

Practical Tips for Optimizing Material Selection

Engineers and manufacturers can streamline material selection with these actionable strategies:

- Align with Application Needs: Choose metals for high-stress components and polymers for cost-effective prototypes.

- Balance Cost and Performance: Evaluate trade-offs between material costs and long-term durability to optimize budgets.

- Conduct Material Testing: Use prototyping and standardized tests (e.g., ASTM) to validate performance before production.

- Prioritize Sustainability: Incorporate biodegradable or recycled materials to meet environmental goals.

- Consult Experts: Collaborate with material specialists to identify the best options for complex projects.

Frequently Asked Questions (FAQs)

What are the most common materials used in 3D printing, and how do they differ?

The most common 3D printing materials include polymers like ABS, PLA, and TPU, metals such as stainless steel and titanium, and composites like carbon fiber-reinforced polymers. Polymers are versatile and cost-effective, with ABS offering durability for functional parts and PLA being biodegradable for eco-friendly prototyping. Metals provide superior strength and precision, ideal for aerospace and medical applications, but require advanced printers. Composites combine lightweight design with high performance, suited for specialized applications like turbine blades. Each material’s properties—strength, flexibility, and printability—determine its suitability for specific projects.

How can I choose the right material for my 3D printing project?

Selecting the right material requires a thorough evaluation of project requirements, including mechanical properties, environmental conditions, and budget constraints. Start by defining the component’s purpose: high-stress parts may need metals like titanium, while prototypes can use cost-effective PLA. Consider environmental factors, such as exposure to heat or chemicals, which may favor ABS over PLA. Testing prototypes under real-world conditions and consulting material data sheets (aligned with ISO or ASTM standards) can guide decisions. Additionally, factoring in sustainability goals may lead to choosing biodegradable or recycled materials to align with eco-conscious priorities.

Are sustainable materials a viable option for 3D printing projects?

Sustainable materials, such as biodegradable PLA and recycled metals, are highly viable for 3D printing, offering environmental benefits without compromising quality. PLA, derived from renewable sources, is ideal for prototyping and non-functional parts, while recycled ABS and metals maintain durability for functional components. These materials reduce carbon footprints and align with circular economy principles, appealing to industries like consumer goods and packaging. However, sustainable options may have limitations, such as PLA’s lower heat resistance, so careful testing is essential to ensure performance meets project demands.

Mastering Material Selection for 3D Printing Excellence

Choosing the right materials for 3D printing is a strategic process that balances technical performance, cost, and sustainability. From versatile polymers like ABS and PLA to high-strength metals like titanium and ICSID: 1052644 and aluminum, and advanced composites like carbon fiber, each material offers unique benefits tailored to specific applications. By carefully evaluating mechanical properties, environmental factors, and budget constraints, engineers and manufacturers can optimize their production outcomes. Industry leaders like Erlas Global demonstrate how expertise in material selection, guided by ISO standards, can deliver exceptional results. Ready to transform your 3D printing projects? Leverage these insights to select the perfect materials and achieve manufacturing excellence.