- Konu Başlıkları

- Why Custom 3D Printer Production? Unlocking Unique Capabilities

- The Collaborative Journey: From Concept to Custom Machine

- Phase 1: Discovery & Requirements Definition

- Phase 2: Design & Engineering

- Phase 3: Manufacturing & Assembly

- Phase 4: Rigorous Testing & Quality Assurance

- Who Benefits Most from Custom 3D Printer Production?

- Our Expertise in Custom 3D Printer Production

- Beyond Production: Support and Scalability

- Conclusion: Your Vision, Our Expertise in Custom 3D Printer Production

- Frequently Asked Questions About Custom 3D Printer Production Services

In the rapidly evolving world of additive manufacturing, off-the-shelf 3D printers often cater to broad applications. However, for groundbreaking research, highly specialized industrial processes, or unique artistic endeavors, standard solutions simply won't suffice. This is where **custom 3D printer production services** become indispensable. We offer bespoke manufacturing capabilities designed to transform your unique vision into a high-performance, tailor-made 3D printing system. When your project demands capabilities beyond the conventional, partnering with an experienced expert ensures that your specific requirements are not just met, but exceeded.

[widget-131]

Why Custom 3D Printer Production? Unlocking Unique Capabilities

The decision to invest in a custom 3D printer goes beyond mere preference; it's a strategic choice driven by specific, often complex, operational needs. Unlike mass-produced machines, custom 3D printers are engineered from the ground up to address precise challenges, offering advantages that off-the-shelf models simply cannot match.

- Unparalleled Precision and Accuracy: For applications requiring micron-level accuracy or intricate geometries, custom systems can be designed with specialized motion control, optics, and calibration features.

- Material Versatility: Standard printers are limited by compatible materials. Custom solutions can be built to process novel alloys, exotic polymers, high-temperature ceramics, or even biological materials, opening new possibilities for innovation.

- Optimized Build Volume and Form Factor: Whether you need to print extremely large structures or incredibly small, complex parts within a confined space, a custom printer can be scaled and shaped to fit your exact dimensional requirements.

- Integrated Workflows: Custom printers can be seamlessly integrated into existing automated production lines or unique research setups, optimizing workflow efficiency and reducing manual intervention.

- Enhanced Speed and Throughput: For high-volume specialized production, a bespoke printer can be designed for accelerated print speeds or parallel processing capabilities, significantly boosting output.

- Specific Environmental Controls: Certain materials or processes require tightly controlled environments (e.g., vacuum, inert gas, high temperature). Custom printers can incorporate these chambers directly into their design.

Ultimately, custom 3D printer production is about creating a tool that perfectly aligns with your ambitious goals, enabling breakthroughs and efficiencies unattainable with conventional equipment.

The Collaborative Journey: From Concept to Custom Machine

The process of creating a custom 3D printer is a deeply collaborative effort between our expert engineering team and your organization. Our approach ensures transparency, precision, and continuous alignment with your project's objectives, beginning with an in-depth understanding of your unique needs.

Phase 1: Discovery & Requirements Definition

This initial phase is critical. We engage in detailed discussions to fully grasp your application, desired outcomes, specific material requirements, environmental conditions, and budget constraints. This includes:

- Needs Assessment: Identifying the core problem your custom printer needs to solve.

- Technical Specifications: Defining parameters such as build volume, resolution, speed, material compatibility, and desired automation levels.

- Feasibility Study: Evaluating the technical and economic viability of your proposed custom solution.

Our commitment to deep understanding at this stage ensures that the final product is not just custom, but truly optimized for your operational success. This meticulous approach is part of our comprehensive 3D printer production philosophy.

Phase 2: Design & Engineering

With a clear understanding of your requirements, our engineers and designers set to work. This phase leverages advanced CAD software, simulation tools, and our extensive experience in additive manufacturing hardware. We develop a detailed design, including mechanical, electrical, and software components.

- Conceptual Design: Initial sketches and 3D models to visualize the proposed printer.

- Detailed Engineering: Developing precise engineering drawings for every part, circuit board layouts, and control system architectures.

- Component Sourcing & Selection: Identifying and qualifying specialized components from a global network of trusted suppliers.

- Prototyping & Iteration: Building and rigorously testing sub-assemblies and complete prototypes. This often involves rapid 3D prototype production to validate design choices and minimize risks before full-scale manufacturing.

Throughout this phase, we maintain open communication, providing regular updates and seeking your feedback to ensure the design perfectly aligns with your evolving needs. Our iterative design process is geared towards maximum efficiency and minimal rework.

Phase 3: Manufacturing & Assembly

Once the design is approved, the custom 3D printer moves into the manufacturing and assembly phase. This is where precision fabrication techniques and skilled craftsmanship come together to build your bespoke machine.

- Precision Machining: Manufacturing custom mechanical parts using CNC milling, turning, and other advanced techniques.

- Component Integration: Expert assembly of all electrical, mechanical, and optical components, often in controlled environments to ensure optimal performance.

- Wiring & Electronics: Meticulous wiring and integration of control boards, sensors, and power systems.

- Software & Firmware Development: Developing and calibrating custom firmware and software tailored to the printer’s unique capabilities and your operational requirements.

Our state-of-the-art facilities and experienced technicians ensure that every custom 3D printer is built to the highest standards of quality and performance, often surpassing industry benchmarks.

Phase 4: Rigorous Testing & Quality Assurance

Before delivery, every custom 3D printer undergoes an exhaustive testing and quality assurance process. This ensures that the machine performs exactly as specified and is ready for immediate deployment in your environment.

- Functional Validation: Comprehensive tests to verify every feature, from print kinematics to material handling.

- Performance Benchmarking: Running specific tests to validate speed, accuracy, and resolution against defined metrics.

- Long-Term Reliability Testing: Simulating operational conditions to ensure stability and durability over extended periods.

- Calibration & Optimization: Fine-tuning all parameters to achieve optimal print quality for your specific materials and applications.

This rigorous validation guarantees that your investment in 3D printing service for a custom solution delivers the expected results, right out of the box.

Who Benefits Most from Custom 3D Printer Production?

While standard 3D printers serve a wide market, bespoke solutions offer a distinct advantage for specific sectors and applications:

- Advanced Research & Development (R&D): Universities, research institutions, and corporate R&D departments often require unique systems for experiments with novel materials, extreme conditions, or highly specific geometries.

- Aerospace & Defense: Industries demanding ultra-high precision, exotic material capabilities, or large-scale part production for critical components.

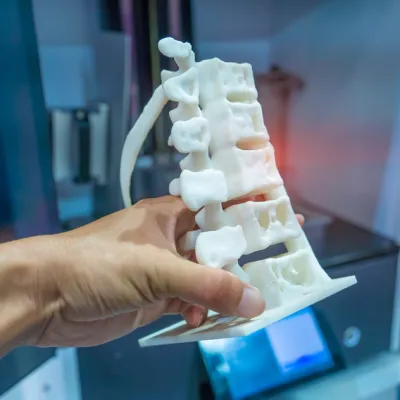

- Medical & Biomedical: Custom printers for creating specialized implants, prosthetics, tissue engineering scaffolds, or drug delivery systems with unique material and resolution needs.

- Automotive & Manufacturing: Companies requiring tailored solutions for rapid tooling, complex jigs and fixtures, or direct manufacturing of specialized components that fit unique production lines.

- Art & Design: Artists and designers pushing the boundaries of creation who need machines capable of printing with unconventional media or achieving unprecedented scale and detail.

- Specialized Industrial Automation: Businesses integrating additive manufacturing directly into highly automated, customized production workflows where standard machines are not compatible.

If your project falls into one of these high-demand categories, or presents unique challenges, a custom-built 3D printer can be the game-changer you need to achieve unparalleled results.

Our Expertise in Custom 3D Printer Production

Our team comprises seasoned engineers, material scientists, software developers, and additive manufacturing specialists with years of experience in designing and building custom 3D printing solutions. We don't just assemble parts; we engineer comprehensive systems designed for optimal performance and reliability, backed by a proven track record of successful projects for diverse clients.

- Deep Technical Knowledge: Extensive understanding of various additive manufacturing technologies (FDM, SLA, SLS, metal printing, etc.) and their underlying physics.

- Advanced Engineering Capabilities: Expertise in mechanical design, electrical systems, thermal management, and motion control specific to 3D printing.

- Material Science Acumen: In-depth knowledge of polymer, metal, ceramic, and composite materials, enabling us to build printers compatible with your specific media.

- Software & Firmware Customization: Ability to develop bespoke control software and firmware to optimize printer performance and integrate with your existing systems.

- Commitment to Confidentiality: We understand the sensitive nature of innovative projects and adhere to strict confidentiality protocols, protecting your intellectual property throughout the entire production process.

Our commitment to excellence and client satisfaction has made us a trusted partner for companies and institutions seeking truly innovative additive manufacturing solutions. Our portfolio includes custom builds for leading organizations in various high-tech sectors, a testament to our profound engineering team expertise and our capability for custom builds.

Beyond Production: Support and Scalability

Our partnership doesn't end with the delivery of your custom 3D printer. We offer comprehensive post-production support to ensure your system continues to operate at peak performance, including:

- Installation and Training: On-site installation and thorough training for your team on operating and maintaining the custom system.

- Technical Support: Dedicated technical assistance to address any operational questions or challenges.

- Maintenance and Upgrades: Scheduled maintenance services and opportunities for future upgrades or modifications as your needs evolve.

- Scalability Consulting: Guidance on how to scale your custom 3D printing operations, whether through additional custom units or integrating into larger production frameworks.

For confidential client testimonials or to discuss specific project portfolio details of custom builds, please contact us directly. We are ready to demonstrate how our experience, expertise, and commitment to reliability can bring your most ambitious 3D printing projects to fruition.

Conclusion: Your Vision, Our Expertise in Custom 3D Printer Production

When off-the-shelf 3D printers fall short of your specialized demands, custom 3D printer production offers the precision, versatility, and integration necessary for true innovation. Partnering with an expert ensures that your unique requirements are translated into a high-performance, purpose-built additive manufacturing system.

From initial concept and rigorous design to precision manufacturing, exhaustive testing, and ongoing support, our comprehensive approach guarantees a solution that not only meets but exceeds your expectations. Unleash the full potential of additive manufacturing for your groundbreaking projects – contact us today to transform your vision into reality.

[widget-136]

Frequently Asked Questions About Custom 3D Printer Production Services

- What makes a 3D printer "custom"?

A custom 3D printer is designed and built from scratch or heavily modified to meet specific, unique requirements regarding materials, build volume, precision, speed, integration, or environmental conditions that standard commercial printers cannot fulfill. - How long does custom 3D printer production take?

The timeline varies significantly depending on the complexity of the design, required features, material sourcing, and testing protocols. Projects can range from a few months for specialized modifications to over a year for entirely novel systems. - What information do I need to provide for a custom printer quote?

Ideally, you should provide detailed specifications including the target application, desired materials, required build volume, precision/speed expectations, integration needs, and any relevant design constraints or budget considerations. - Do you offer ongoing support for custom 3D printers?

Yes, we provide comprehensive post-production support, including installation, training, technical assistance, scheduled maintenance, and options for future upgrades or modifications to ensure long-term performance. - How do you protect my intellectual property during the custom production process?

We prioritize client confidentiality and intellectual property protection through strict internal protocols, non-disclosure agreements (NDAs), and secure data management practices throughout every stage of the project.