- Konu Başlıkları

- The Shift from Prototyping to Production

- Key Technological Advancements in 3D Printer Production

- 1. High-Speed Printing Mechanisms

- 2. Improved Material Science

- 3. Automation & Industry 4.0 Integration

- 4. Advanced Slicing Software and AI Optimization

- 5. Multi-Material & Hybrid Printing

- 6. Larger Build Volumes and Better Resolution

- Business Impacts: What These Advancements Mean for You

- Cost Considerations in Modern 3D Production

- Erla’s Global: Embracing the Future of 3D Printer Production

- Looking Ahead: What’s Next for 3D Printer Production?

- Leading the Way in Precision and Innovation

- Frequently Asked Questions

The landscape of 3D printer production has evolved at an unprecedented pace, reshaping how industries design, prototype, and manufacture components. What began as a novelty for rapid prototyping has grown into a transformative manufacturing method capable of high-precision, end-use part production.

For innovators and technical professionals, keeping up with these advancements is not just beneficial—it’s essential. Whether you're working in aerospace, healthcare, automotive, or consumer tech, the latest trends in 3D printer production hold the power to optimize workflows, reduce costs, and unlock new levels of design freedom.

This article explores the most impactful innovations, industry shifts, and technologies revolutionizing 3D printer production, with expert insights from Erlas Global’s own additive manufacturing operations.

[widget-131]

The Shift from Prototyping to Production

Historically, 3D printing was primarily used to create low-cost prototypes that helped engineers test form and fit. However, as machine precision, material diversity, and software integration have advanced, manufacturers now routinely rely on additive manufacturing for:

- Functional end-use parts

- Tooling components

- Bridge production between design phases

- Spare part replacements

- Custom and personalized goods

This shift toward production-grade applications is made possible by breakthroughs in speed, accuracy, consistency, and scalability.

Key Technological Advancements in 3D Printer Production

1. High-Speed Printing Mechanisms

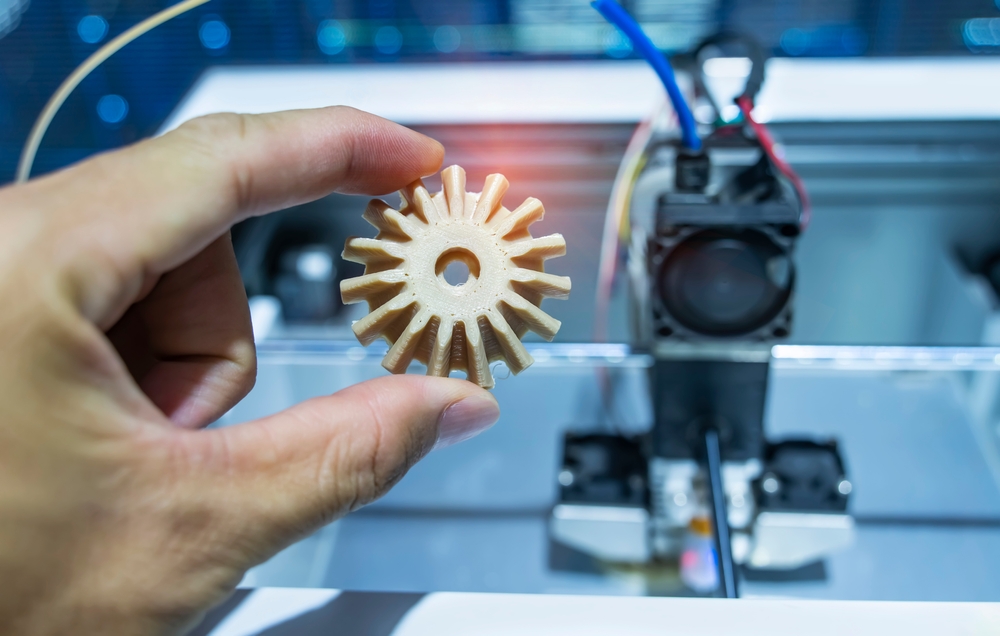

Recent innovations like Multi Jet Fusion (MJF), Continuous Liquid Interface Production (CLIP), and Binder Jetting have significantly increased print speeds without compromising detail. These technologies enable manufacturers to move from days-long build cycles to same-day output for small-to-medium batch parts.

In parallel, faster heating and cooling systems allow thermoplastics to bond efficiently, reducing warping and post-processing needs.

2. Improved Material Science

Material options have exploded—from standard PLA and ABS to carbon fiber-infused composites, PEEK, ULTEM, ceramics, and metal powders. Many materials are now tailored for:

- Chemical resistance

- Electrical insulation

- Flame retardancy

- Biocompatibility

These advancements extend the use of 3D printing into fields that demand high-performance materials, such as aerospace and medical implants.

At Erlas Global’s 3D printer production facility, clients gain access to a curated portfolio of advanced materials selected based on mechanical, thermal, and application-specific needs.

3. Automation & Industry 4.0 Integration

The integration of 3D printer systems into Industry 4.0 workflows has opened new doors for smart manufacturing. Features include:

- Automated print queues

- Remote monitoring via IoT

- Self-calibrating printers

- Cloud-based slicing and diagnostics

These systems reduce human error, allow real-time quality control, and enable lights-out manufacturing for small-batch or overnight operations.

Erlas Global’s internal systems now leverage these capabilities to ensure high uptime and consistent throughput, especially during peak prototyping or pilot production schedules.

4. Advanced Slicing Software and AI Optimization

Software is catching up with hardware. Next-gen slicing tools now use AI and machine learning to:

- Optimize support structure placement

- Reduce material waste

- Adjust parameters mid-build to compensate for thermal or layer inconsistencies

- Predict print failures before they happen

These smart slicing capabilities enhance build reliability and efficiency. The result? Better parts, lower costs, and faster delivery cycles.

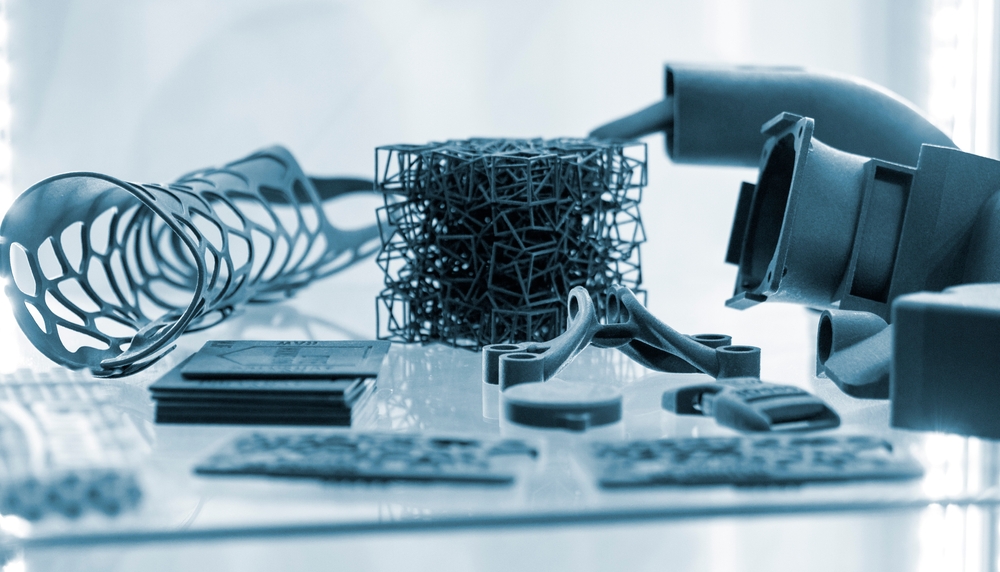

5. Multi-Material & Hybrid Printing

One of the most exciting developments is the ability to print using multiple materials in a single run. Hybrid machines can now switch between:

- Flexible and rigid polymers

- Conductive and non-conductive materials

- Plastic and metal components

This is especially useful in electronics, soft robotics, and wearables, where diverse material properties are essential.

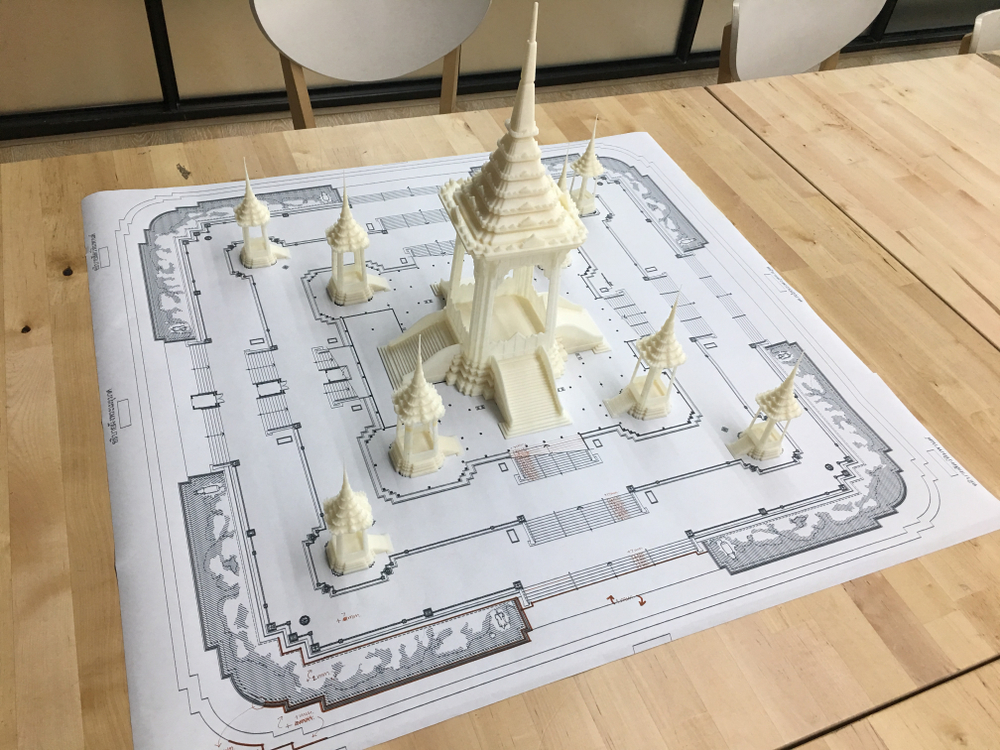

6. Larger Build Volumes and Better Resolution

While early machines were limited in size and detail, today’s industrial printers offer:

- Build volumes up to 1m³ or more

- Layer resolution as fine as 10 microns

- Tolerances below ±0.05 mm

This enables high-precision printing of both miniature components and large parts such as automotive bumpers or architectural models.

Business Impacts: What These Advancements Mean for You

The practical implications of these advancements are immense:

- Shorter Time to Market

Rapid iteration and production mean businesses can test and launch products faster than ever before. - Customization at Scale

Mass customization is now possible—offering unique products without increasing unit costs. - Sustainable Production

With localized printing, less waste, and digital inventory systems, 3D printing supports sustainability goals. - Cost Reduction

Reduced tooling, less setup time, and lower labor involvement all lead to significant cost savings, particularly for short-run and on-demand manufacturing.

These benefits are especially appealing to startups and mid-sized firms that may not have the budget for traditional mass production but still need flexible, responsive output.

For example, many clients turn to Erlas Global when they want to order custom 3D printer prototypes or small batches that would be economically unfeasible through other methods.

Cost Considerations in Modern 3D Production

While the entry price of consumer-grade 3D printers has decreased, professional 3D printer production remains a nuanced cost structure. Key pricing factors include:

- Print time and machine type

- Material quantity and type

- Complexity and support structures

- Post-processing requirements

- Volume (prototype vs batch)

For instance, printing a small PLA prototype may cost under $50, while a metal part with tight tolerances and post-processing can reach hundreds or even thousands.

To understand the full breakdown of expenses, Erlas Global provides transparent quotes through its cost of 3D printer production resource page.

Erla’s Global: Embracing the Future of 3D Printer Production

As advancements continue to redefine additive manufacturing, Erlas Global is at the forefront—investing in next-generation equipment, adopting predictive analytics, and training multidisciplinary teams.

Their integrated approach includes:

- In-house design support

- Multi-technology production lines

- Strict QA processes

- Automated print farm scheduling

- Fast-track prototyping options for urgent R&D projects

By combining expertise with adaptability, Erlas Global empowers its clients to ride the wave of innovation—not just follow it.

Looking Ahead: What’s Next for 3D Printer Production?

The future is bright—and layered. Some developments on the horizon include:

- 4D printing: Smart materials that change shape over time

- Bio-printing: For human tissue, organs, and pharmaceuticals

- AI-driven part design: Generative design based on performance simulations

- Full-color, texture-integrated printing: For consumer-ready visual models

In this rapidly evolving space, manufacturers that stay ahead of the curve will lead their industries. And those who align with partners like Erlas Global gain access not only to advanced tools—but to a forward-thinking strategy for growth.

Leading the Way in Precision and Innovation

The advancements in 3D printer production are not just about machines—they’re about possibility. With smarter systems, broader material choices, and deeper integration into digital workflows, additive manufacturing is stepping into its next era.

Erlas Global is helping lead that charge—equipping clients with the expertise, infrastructure, and flexibility to turn complex ideas into tangible outcomes. Whether you’re developing a single-use medical device or exploring new product categories, the future of making is already here—and it’s being printed.

Frequently Asked Questions

How have recent advancements changed 3D printer production?

Recent advancements have transformed 3D printing from a prototyping tool into a full-scale production solution. Improvements in print speed, material quality, AI-assisted slicing, and automation have enabled manufacturers to create durable, high-precision parts with faster turnaround times and lower costs. These technologies also support on-demand and distributed manufacturing models.

What materials are now available that weren’t before?

Previously limited to basic plastics, today’s material options include carbon fiber-reinforced polymers, high-performance thermoplastics like PEEK and ULTEM, and even metal alloys like titanium and stainless steel. Each material offers specific benefits in terms of strength, temperature resistance, or flexibility, expanding the scope of applications.

Can 3D printers now produce parts that meet industrial standards?

Yes. Modern industrial 3D printers achieve tolerances within ±0.05 mm and layer resolutions as fine as 10 microns. Combined with certified materials and post-processing options like annealing or machining, parts can meet ISO and ASTM standards for functional, safety-critical applications.

What industries benefit most from recent 3D printing innovations?

Sectors such as aerospace, medical, automotive, and electronics benefit the most. Innovations enable lightweight, complex structures in aircraft; patient-specific implants; rapid tooling in car production; and customized casings or conductive elements in electronics.

Is 3D printer production cost-effective for low-volume manufacturing?

Absolutely. The elimination of tooling, reduced labor, and ability to print only what’s needed make 3D printing highly cost-effective for low-volume or custom manufacturing. Erlas Global offers tailored solutions to ensure even small-batch orders are affordable and efficient.