- Konu Başlıkları

- The Digital Foundation: Design and Simulation Technologies

- Precision Fabrication: Bringing Digital Designs to Life

- Automation and Robotics: Revolutionizing Assembly

- Rigorous Quality Control and Testing Technologies

- Beyond the Core: Supporting Technologies

- Erlas Global's Commitment to Advanced Production Technologies

- Conclusion: The Engine of Additive Manufacturing Evolution

- Frequently Asked Questions About Technologies in 3D Printer Production

Beyond the impressive capabilities of 3D printers themselves lies an equally sophisticated world: the manufacturing process of these groundbreaking machines. Producing a high-performance 3D printer demands more than just assembling parts; it requires a symphony of advanced technologies in 3D printer production. From the initial digital blueprint to the final rigorous testing, cutting-edge machinery, software, and automation play a pivotal role. For engineers and tech enthusiasts, understanding these underlying manufacturing innovations reveals why some 3D printers stand out in terms of precision, reliability, and functionality. Let's delve into the core technologies that bring these complex devices to life.

[widget-131]

The Digital Foundation: Design and Simulation Technologies

Every physical 3D printer begins its existence as a digital model. The initial phase of 3D printer production heavily relies on powerful software tools that enable intricate design, detailed analysis, and precise simulation, laying the groundwork for efficient manufacturing.

- Computer-Aided Design (CAD) Software: This is where the 3D printer's entire structure, every component, and all sub-assemblies are meticulously designed in a virtual environment. CAD software allows engineers to create precise 3D models, ensuring dimensional accuracy and component fit before any physical manufacturing begins.

- Computer-Aided Manufacturing (CAM) Software: Bridging the gap between design and production, CAM software translates CAD models into instructions for manufacturing machinery like CNC machines. It optimizes tool paths and operational sequences for efficient part fabrication.

- Finite Element Analysis (FEA) & Simulation Tools: These advanced software packages are used to simulate how the printer's components will behave under various stresses, temperatures, and operational loads. FEA helps identify potential weak points, optimize material usage, and ensure structural integrity and thermal stability, contributing to the overall reliability of the final product.

- Digital Twin Technology: Increasingly, manufacturers are creating digital twins of their production lines or even individual printers. These virtual replicas allow for real-time monitoring, predictive maintenance, and simulation of changes, optimizing the entire manufacturing process and product lifecycle.

These digital technologies are fundamental, allowing for rapid iteration, error reduction, and cost optimization even before physical prototyping begins. They enable a 'first-time-right' approach, significantly impacting the overall cost of 3D printer production.

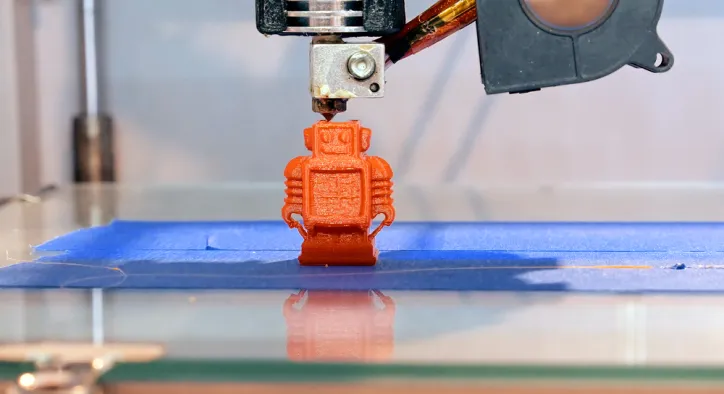

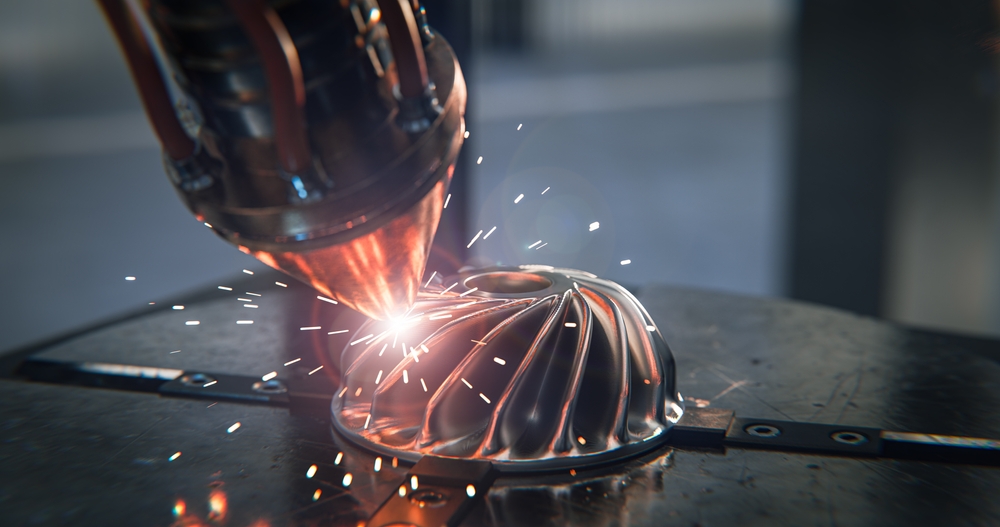

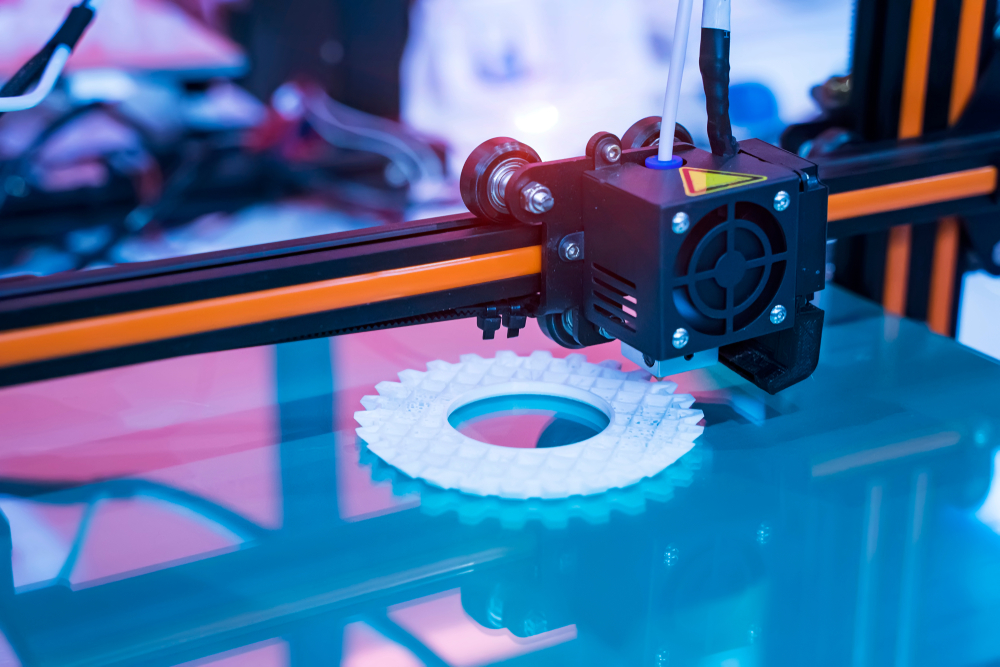

Precision Fabrication: Bringing Digital Designs to Life

Once components are designed and optimized digitally, precision manufacturing technologies are employed to fabricate the physical parts that will make up the 3D printer. Accuracy at this stage is crucial for the final product's performance.

- CNC (Computer Numerical Control) Machining: CNC milling, turning, and grinding machines are vital for producing high-precision metal and plastic components, such as printer frames, gantry systems, hot end components, and motor mounts. These machines offer unparalleled accuracy and repeatability.

- Laser Cutting & Welding Systems: Lasers are used for precisely cutting metal sheets for frames and enclosures, as well as for highly accurate welding of delicate components, ensuring clean cuts and strong bonds.

- Injection Molding: For mass-produced plastic components like casings, covers, and internal structural elements, injection molding offers a cost-effective and highly repeatable process, producing identical parts at high volumes.

- Advanced Surface Treatment Technologies: Techniques like anodizing, powder coating, and precise polishing are applied to components to enhance durability, corrosion resistance, thermal performance, and aesthetic appeal.

These fabrication technologies ensure that every part of the 3D printer meets stringent dimensional and material quality standards, which is fundamental for the reliability and precision of the final printing machine. Our commitment to these technologies allows us to consistently deliver high-quality outputs, similar to our approach in providing top-tier 3D printing service to our clients.

Automation and Robotics: Revolutionizing Assembly

Modern 3D printer production lines increasingly rely on automation and robotics to enhance efficiency, reduce labor costs, and ensure consistent quality, especially for high-volume manufacturing.

- Robotic Arms: Multi-axis robotic arms are deployed for repetitive assembly tasks, such as screwing in components, applying adhesives, placing intricate electronic parts, and material handling. Their precision and tireless operation significantly speed up the assembly process.

- Automated Guided Vehicles (AGVs) / Autonomous Mobile Robots (AMRs): These intelligent robots transport components and sub-assemblies between different workstations, optimizing material flow and reducing manual logistics within the factory.

- Automated Component Feeding Systems: Vibratory bowls, feeders, and pick-and-place machines ensure a continuous and precise supply of small components to assembly stations, minimizing human intervention.

- Automated Inspection & Testing Stations: Robots equipped with vision systems or specialized sensors perform automated quality checks at various stages of assembly, flagging defects instantly and reducing the need for manual inspection.

The integration of these automation technologies creates highly efficient and consistent production environments, allowing manufacturers to meet increasing demand while maintaining stringent quality control. This is a critical aspect of modern, large-scale 3D printer manufacturing.

Rigorous Quality Control and Testing Technologies

Even with advanced fabrication and assembly, a 3D printer is only as good as its quality control. The technologies used for testing and validation ensure that every unit performs flawlessly upon delivery.

- Coordinate Measuring Machines (CMM): These highly precise devices are used to measure the physical geometric characteristics of a component, verifying that it meets design specifications with micron-level accuracy.

- Automated Optical Inspection (AOI) Systems: Using cameras and sophisticated algorithms, AOI systems rapidly inspect printed circuit boards (PCBs), solder joints, and surface finishes for defects, ensuring electronic integrity.

- Functional Test Benches: Customized test stands simulate real-world operating conditions. They perform comprehensive functional checks on fully assembled printers, verifying movements, heating, extrusion, and software communication.

- Thermal Imaging & Environmental Testing: Infrared cameras monitor heat distribution within the printer during operation, identifying potential overheating issues. Environmental chambers simulate various temperatures and humidity levels to ensure performance across different conditions.

- Data Analytics and Predictive Maintenance: Collecting data from testing and in-field performance allows for statistical process control (SPC) and predictive maintenance, identifying trends and potential issues before they cause failures. This also feeds back into refining future designs.

These exhaustive testing procedures guarantee the reliability and longevity of the 3D printers produced, reinforcing the manufacturer's commitment to delivering top-tier equipment. For those looking to order custom 3D printer prototypes, these rigorous testing protocols ensure the bespoke solutions meet their unique, demanding specifications.

Beyond the Core: Supporting Technologies

Several other technologies play crucial supporting roles throughout the 3D printer production lifecycle, enhancing efficiency and sustainability.

- Enterprise Resource Planning (ERP) Systems: ERP software integrates various business functions, including supply chain management, inventory control, production planning, and finance. This provides a holistic view of operations, optimizing resource allocation and efficiency.

- Robotic Process Automation (RPA): RPA tools automate repetitive administrative tasks, such as data entry, order processing, and report generation, freeing up human resources for more complex problem-solving and innovation.

- Advanced Logistics and Tracking: Sophisticated logistics software and GPS tracking systems ensure efficient and secure transportation of raw materials and finished products globally, minimizing delays and losses.

- Sustainable Manufacturing Technologies: Innovations in energy-efficient machinery, waste reduction processes (e.g., material recycling programs for scrap components), and renewable energy integration within factories contribute to an eco-friendlier production footprint.

The synergy of these diverse technologies creates a robust and highly efficient production ecosystem, capable of delivering high-quality 3D printers to a demanding global market.

Erlas Global's Commitment to Advanced Production Technologies

At Erlas Global, our strength in 3D printer production stems directly from our strategic adoption and mastery of these advanced manufacturing technologies. We don't just use technology; we integrate it intelligently to ensure every 3D printer we produce is a testament to precision, reliability, and innovation.

Our facilities are equipped with state-of-the-art CNC machining centers, advanced robotic assembly lines, and comprehensive automated quality inspection systems. Our engineering teams utilize the latest CAD/CAM and simulation software, pushing the boundaries of design for manufacturability. We constantly invest in R&D to incorporate new techniques and optimize our processes, reflecting our deep understanding of the evolving landscape of 3D printer manufacturing.

This dedication to technological excellence is a core pillar of our E-E-A-T, demonstrating our profound experience, technical expertise, authoritative command of the field, and trustworthiness as a leading manufacturer. When you partner with us, you're choosing a future-forward approach to 3D printer production, ensuring your equipment is built with the best technologies available.

Conclusion: The Engine of Additive Manufacturing Evolution

The production of 3D printers is a complex, multi-faceted process driven by a sophisticated array of technologies. From the initial digital design and precision component fabrication to automated assembly, rigorous quality control, and intelligent supply chain management, each technological layer contributes to the final product's performance and reliability.

As the additive manufacturing industry continues its rapid growth, the underlying production technologies will evolve further, enabling even greater precision, speed, and efficiency. Understanding these innovations provides invaluable insight into the future of manufacturing itself. By embracing and mastering these advanced technologies, companies like Erlas Global ensure that the tools of tomorrow's innovation are built with today's unparalleled technological prowess.

Frequently Asked Questions About Technologies in 3D Printer Production

- What role does AI play in 3D printer production?

AI is increasingly used for optimizing production processes, predictive maintenance of manufacturing equipment, automating quality inspection (e.g., through AI-powered vision systems), and even in supply chain forecasting and risk management. - Are all 3D printers manufactured using the same technologies?

No. While core principles apply, the specific technologies vary. High-volume desktop FDM printers may use more automated assembly, while industrial-grade metal 3D printers require extremely precise CNC machining and specialized calibration equipment. - How does automation impact the cost of 3D printer production?

Automation can significantly reduce labor costs, improve manufacturing consistency (leading to less rework/defects), and increase throughput. While initial investment is high, it typically leads to lower per-unit costs at scale. - What is the most critical technology for 3D printer manufacturing precision?

Precision is a combination of many technologies, but highly accurate CNC machining for structural components and advanced calibration systems (often laser-based or vision-system-driven) during assembly and testing are paramount. - How does Erlas Global ensure its production technologies are up-to-date?

We maintain an active R&D department focused on manufacturing processes, regularly invest in upgrading our machinery, participate in industry consortia, and actively recruit talent with expertise in emerging industrial technologies.