- Konu Başlıkları

- The Rising Importance of Quality in 3D Printer Production

- Key Elements of a Robust Quality Control Strategy

- 1. Design Verification and Digital Simulation

- 2. Material Qualification and Traceability

- 3. Machine Calibration and Maintenance

- 4. Layer-by-Layer Monitoring

- 5. Post-Processing Controls and Final Inspection

- Standards and Certifications in 3D Printer Production

- The Role of Data in Quality Assurance

- Cost vs Quality: Finding the Balance

- How Erlas Global Ensures Quality Unit by Unit

- Raising the Bar: Why Unit-Level Quality Matters

- Every Unit, Every Time: Quality Without Compromise

- Frequently Asked Questions

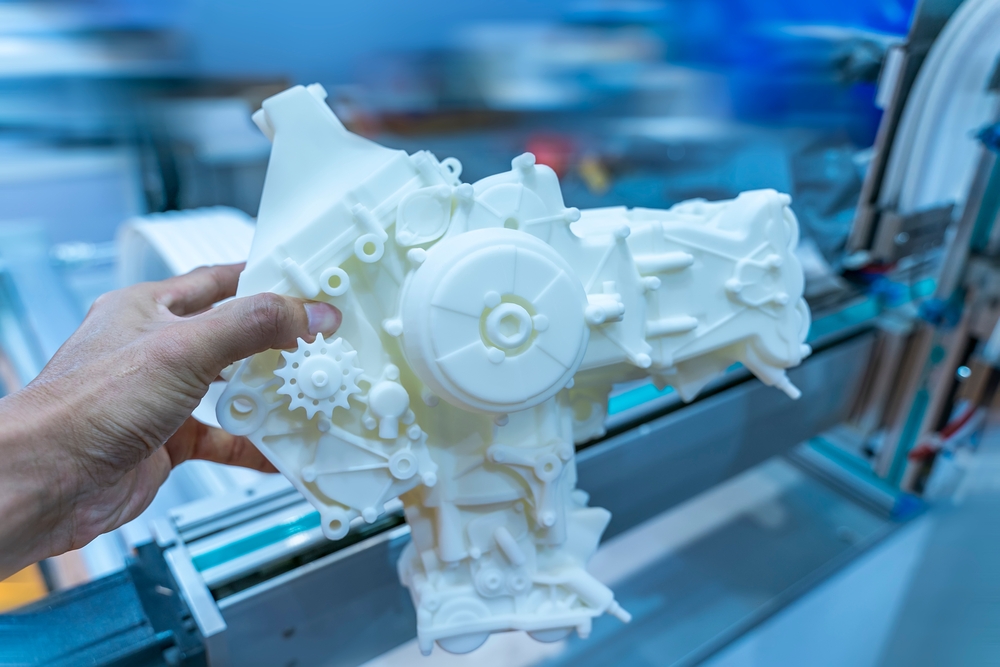

In the world of 3D printer production, consistency is not a luxury—it’s a requirement. As 3D printing continues its evolution from prototyping to full-scale manufacturing, the demand for precise, reliable, and reproducible results grows exponentially. For quality assurance engineers, production supervisors, and brand managers, this shift presents a unique challenge: how to ensure that every single unit meets strict specifications, regardless of the complexity or material used.

This article provides a deep dive into the methodologies, technologies, and workflows that enable companies like Erlas Global to maintain uncompromising quality standards across every 3D printed part, from first to final unit.

[widget-131]

The Rising Importance of Quality in 3D Printer Production

As the 3D printing industry matures, it is increasingly being used not only for design validation but also for small-batch and end-use production. In this context, quality control moves from being a convenience to being critical for brand trust, functional performance, and regulatory compliance.

Poor quality in 3D printing can lead to:

- Dimensional inaccuracies

- Inconsistent mechanical strength

- Surface deformities

- Material inconsistencies

- Failures during part use or assembly

To address these risks, rigorous quality control systems must be embedded throughout the production pipeline—not just at the end.

Key Elements of a Robust Quality Control Strategy

Let’s examine the essential components that make up an effective quality control system in additive manufacturing.

1. Design Verification and Digital Simulation

Quality begins before the first layer is printed. A well-structured QA strategy starts at the design stage with:

- DFAM (Design for Additive Manufacturing) reviews

- Finite Element Analysis (FEA) for stress testing

- Topology optimization to reduce material waste without compromising strength

- Thermal simulations to predict deformation or warping

Erlas Global integrates these simulations into their pre-production workflow, helping eliminate failure risks before production begins.

2. Material Qualification and Traceability

Not all filaments, powders, or resins are created equal. Even within the same material category, variations in supplier quality can lead to unpredictable results.

High-performing manufacturers maintain:

- Certified material databases

- Lot tracking for traceability

- Moisture control systems for hygroscopic materials

- Pre-processing inspections for granule/powder integrity

At Erlas Global, each print job is associated with a complete material audit trail, ensuring full transparency and accountability.

3. Machine Calibration and Maintenance

Repeatability relies on tight machine control. Consistent output demands:

- Automated bed leveling

- Nozzle calibration and extrusion checks

- Temperature uniformity tests

- Scheduled preventive maintenance

Each printer at Erlas Global is validated using Statistical Process Control (SPC) methodologies, with key performance metrics tracked and analyzed over time.

4. Layer-by-Layer Monitoring

In traditional manufacturing, defects may only become visible at the end. With additive manufacturing, quality can be assessed in real-time as each layer is formed.

Advanced 3D printers now include:

- Optical cameras for surface scanning

- Infrared thermography to detect hot spots

- Laser displacement sensors to measure layer height deviations

- Closed-loop feedback systems for auto-correction

These automated inspection systems allow manufacturers to identify and correct problems as they arise—not after the print is complete.

A great example is Erlas Global’s implementation of live monitoring within their 3D printer production lines, significantly reducing part rejection rates.

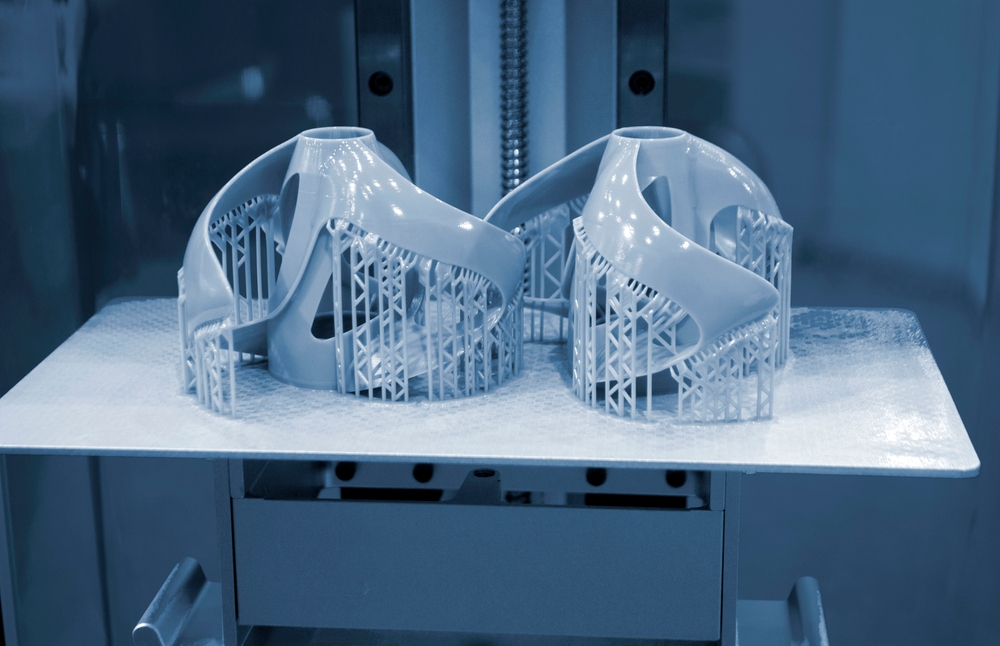

5. Post-Processing Controls and Final Inspection

Even after a successful print, quality control doesn’t stop. Post-processing steps introduce additional opportunities for variability, which must be tightly managed.

Typical procedures include:

- Support removal under inspection

- CNC machining or polishing with tolerancing

- UV curing for SLA parts

- Dimensional measurement using coordinate measuring machines (CMMs)

- Surface roughness checks using profilometers

Parts destined for aerospace or healthcare are also subjected to fatigue and pressure tests to validate performance under real-world conditions.

Standards and Certifications in 3D Printer Production

To build trust and establish manufacturing credibility, companies must align with industry-wide standards. Common benchmarks include:

- ISO 9001 – General quality management

- ISO/ASTM 52900–52930 series – Additive manufacturing technical standards

- AS9100 – Aerospace sector requirements

- ISO 13485 – Medical devices quality control

- RoHS/REACH – Environmental compliance for materials

Erlas Global follows ISO-aligned protocols, offering full documentation for audits and third-party certification requirements—an essential practice when clients order custom 3D printer prototypes with mission-critical performance expectations.

The Role of Data in Quality Assurance

Modern additive manufacturing doesn’t just produce parts—it produces data. By collecting and analyzing operational metrics such as:

- Print head movement

- Layer temperature

- Environmental humidity

- Cooling rates

- Power consumption per unit

QA teams can build predictive models to flag anomalies before defects occur.

Erlas Global uses this data to generate a quality fingerprint for each part, helping isolate failure trends and drive continuous improvement.

Cost vs Quality: Finding the Balance

It’s a common misconception that tighter quality controls always lead to higher costs. In fact, a proactive QA strategy can reduce long-term expenses by minimizing:

- Material waste

- Labor for rework

- Shipping defective parts

- Warranty claims

- Customer dissatisfaction

A detailed quote from Erlas Global outlines all factors influencing the cost of 3D printer production—including built-in quality checkpoints—so clients can make informed, cost-effective choices.

How Erlas Global Ensures Quality Unit by Unit

With dozens of simultaneous print jobs running at any time, Erlas Global employs a scalable, automated quality control system that includes:

- Pre-print validation

- Automated camera monitoring

- QR-coded traceability for each part

- In-line defect tracking

- Final manual inspection and documentation

These protocols ensure that whether a client needs a single prototype or 500 small-batch units, each piece meets the same exacting standard.

Raising the Bar: Why Unit-Level Quality Matters

In batch production, average quality isn’t enough. In 3D printing, the challenge is ensuring that every single part—regardless of when or how it’s printed—performs exactly as intended.

That’s why quality control is not just a department—it’s a philosophy. Erlas Global doesn’t wait for problems to occur. They prevent them through systemized checks, skilled personnel, and data-driven decision-making.

Every Unit, Every Time: Quality Without Compromise

In an era where personalization and speed dominate the manufacturing conversation, maintaining unit-level quality control in 3D printer production is a competitive advantage—and a brand promise.

Through SPC methods, real-time monitoring, and compliance with global standards, Erlas Global ensures not only consistency but confidence. Whether you're launching a new product, replacing a critical component, or scaling up production, you can trust every piece will meet or exceed expectations.

Frequently Asked Questions

What is Statistical Process Control (SPC) in 3D printing?

SPC is a quality control method that uses statistical tools to monitor and control production processes. In 3D printing, SPC tracks variables such as layer height, extrusion rate, and environmental conditions. By analyzing trends and identifying deviations early, manufacturers can prevent defects before they affect the final part. Erlas Global applies SPC across all printers to maintain consistency and traceability.

How do automated inspection systems work during printing?

Automated systems use sensors and cameras to inspect each layer during the build. Optical sensors detect visual anomalies, infrared sensors monitor temperature, and displacement gauges measure surface variations. These systems feed data into software that halts or adjusts the print if issues arise, reducing waste and ensuring dimensional accuracy.

Can I request documentation for quality control during an order?

Yes. Erlas Global provides full quality documentation upon request, including machine calibration logs, material batch certifications, SPC reports, and post-process inspection data. This is particularly valuable for regulated industries like aerospace and medical device production.

Is it more expensive to request strict quality controls?

Not necessarily. While quality control adds steps to production, it also reduces failure rates, rework, and returns—saving money in the long run. Erlas Global integrates many QC processes into their base workflows, ensuring clients benefit from high standards without significant cost increases.

Do all 3D printing technologies support the same level of quality control?

No. Technologies like SLS and SLA offer better opportunities for in-process control due to their thermal and mechanical behavior. FDM, while affordable, requires more frequent calibration. Erlas Global selects the appropriate technology and tailors QC protocols accordingly for each project.