- Konu Başlıkları

- The Inception: Early Concepts of Additive Manufacturing (1970s–1980s)

- Birth of the First Commercial 3D Printer (1980s)

- 1990s: Industrial Adoption and Technical Refinement

- The Democratization of 3D Printing (2000s–2010s)

- 2010s–2020s: Automation, AI, and Scale

- Timeline Summary of 3D Printer Manufacturing Evolution

- Erla’s Global and the Legacy of Innovation

- Frequently Asked Questions

- From Prototype Dreams to Industrial Reality: The Living History of 3D Printer Production

From the earliest conceptual models of additive manufacturing to today's AI-integrated, high-resolution industrial 3D printers, the history of 3D printer production is a compelling journey through innovation, engineering, and ambition. Often mistakenly perceived as a recent technology, 3D printing’s origins date back over four decades. Understanding its evolution not only honors the pioneers who shaped the field but also sheds light on the technical philosophies behind today’s most sophisticated machines.

This article provides a scholarly yet accessible narrative of how 3D printer manufacturing evolved—highlighting the milestones, the inventors, the paradigm shifts, and the global forces that turned prototyping into a scalable, full-spectrum manufacturing solution.

[widget-131]

The Inception: Early Concepts of Additive Manufacturing (1970s–1980s)

The foundational principles of additive manufacturing were formulated in the 1970s, primarily as part of experimental fabrication studies in mechanical engineering and materials science. Unlike subtractive manufacturing (which removes material from a block), the idea was to build up parts layer by layer—a concept inspired by natural formation processes like crystal growth.

In 1981, Japanese researcher Dr. Hideo Kodama proposed a system using UV light to cure photopolymers layer by layer, creating solid forms. Though he never commercialized the technology, his work is now regarded as the first formal documentation of 3D printing.

Birth of the First Commercial 3D Printer (1980s)

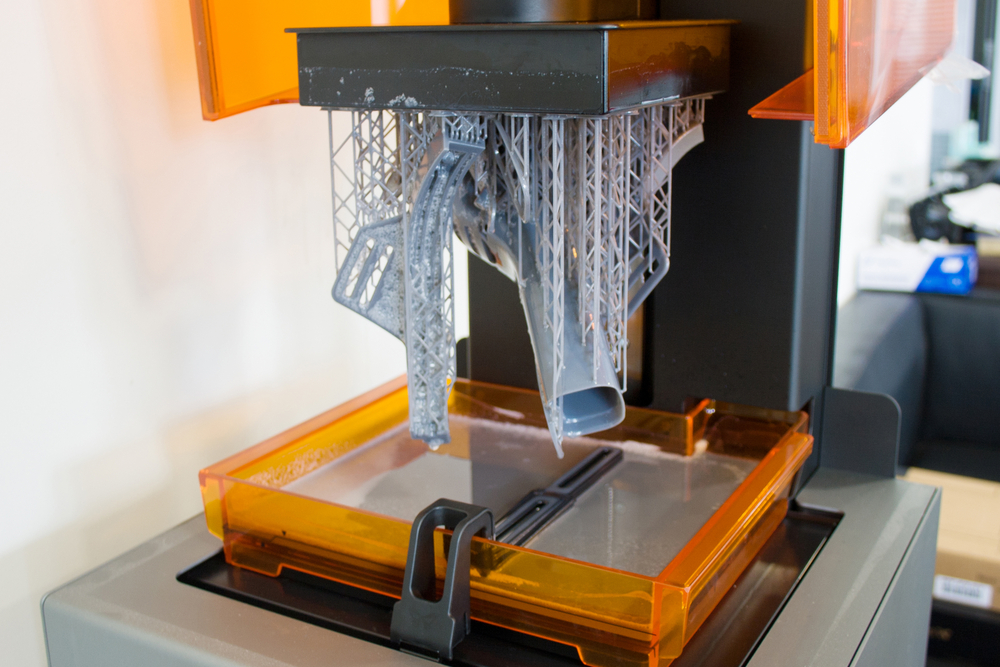

The first breakthrough came in 1986 when Charles Hull, an American engineer, patented stereolithography (SLA)—a process that used a UV laser to solidify thin layers of resin. Hull also co-founded 3D Systems, launching the first commercial 3D printer, the SLA-1, in 1987.

Key attributes of the SLA-1:

- High-resolution printing for concept modeling

- Resin-based technology for fine details

- Primarily used in automotive and aerospace sectors

This era laid the groundwork for various 3D printing techniques such as:

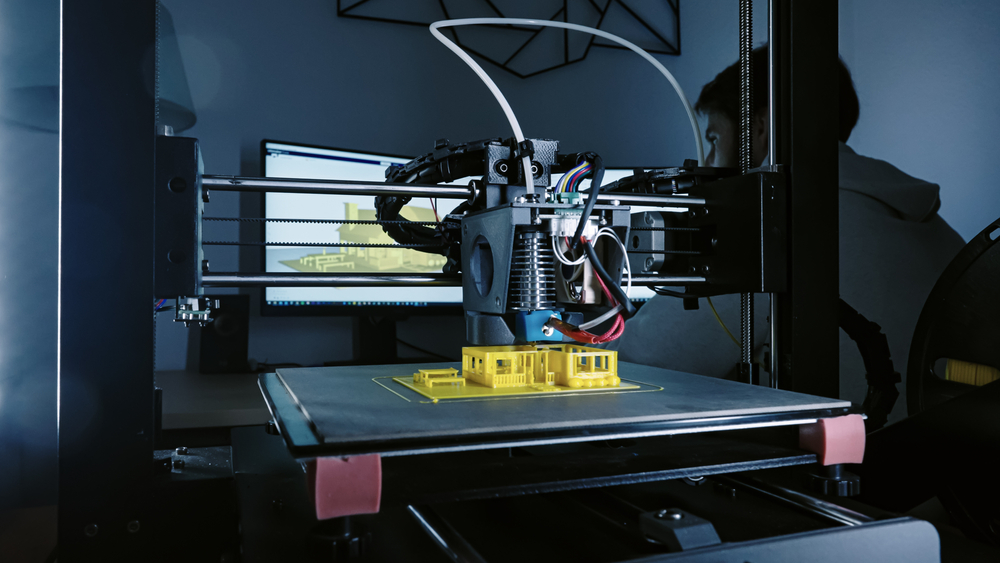

- Fused Deposition Modeling (FDM), developed by Scott Crump in 1989

- Selective Laser Sintering (SLS), introduced by Carl Deckard in the same decade

These developments diversified materials usage—from resins to thermoplastics and powdered metals—and opened doors to rapid prototyping in industrial design.

1990s: Industrial Adoption and Technical Refinement

The 1990s saw early adoption of 3D printing in specialized industries. Automotive manufacturers began using 3D printed parts for wind tunnel testing and component modeling. Medical fields experimented with bio-compatible materials for prosthetics and surgical planning.

During this time, the cost of 3D printer production remained prohibitively high for consumer markets, but the industrial value was clear. Companies focused on:

- Increasing build volumes

- Improving material tolerances

- Reducing print times

As research intensified, intellectual property surrounding 3D printing proliferated. Patent portfolios expanded, locking in commercial dominance for a handful of early players like Stratasys and EOS.

The Democratization of 3D Printing (2000s–2010s)

When key FDM patents expired in the early 2000s, a wave of open-source development swept through the maker community. Platforms like RepRap and later MakerBot made affordable desktop 3D printing accessible to hobbyists, educators, and entrepreneurs.

This era transformed 3D printing from a corporate tool into a cultural movement. It also prompted renewed innovation in printer design, materials science, and software interfaces.

At the same time, industrial systems advanced rapidly:

- Multi-material printing allowed for soft and rigid components in a single part.

- Selective Laser Melting (SLM) facilitated the use of metal powders in aerospace-grade components.

- Hybrid machines combined additive and subtractive processes.

As more industries adopted the technology, manufacturing companies sought reliable 3D printing services to support everything from custom tooling to end-use parts.

2010s–2020s: Automation, AI, and Scale

The modern phase of 3D printer manufacturing is marked by convergence with smart manufacturing systems. From machine learning-powered print optimization to automated build plate changes, today’s machines integrate with ERP systems and robotics for seamless workflows.

Key characteristics of this era:

- Industrial-scale metal 3D printing for aerospace and automotive parts

- ISO 9001 and AS9100 certifications for manufacturing compliance

- Automated quality control using embedded cameras and sensors

Erlas Global, for example, offers custom 3D printer prototypes with precision matching industry specifications and compliance needs, responding to the growing complexity of client demands.

Timeline Summary of 3D Printer Manufacturing Evolution

| Year | Innovation/Milestone |

|---|---|

| 1981 | Kodama proposes UV-based layer-by-layer printing |

| 1986 | Hull patents SLA; 3D Systems founded |

| 1989 | FDM and SLS technologies emerge |

| 1990s | Industrial adoption and material expansion |

| Early 2000s | Open-source movement begins (RepRap, MakerBot) |

| 2010s | Metal 3D printing scales; hybrid machines introduced |

| 2020s | AI, robotics, and certification-led production |

Erla’s Global and the Legacy of Innovation

Though the historical foundations of 3D printer production are global, modern advancements are being driven by companies like Erla’s Global. Our manufacturing systems align with the legacy of precision, flexibility, and rapid prototyping that has defined this industry since its inception.

Through ISO-certified processes, high-end SLA/FDM/SLS capabilities, and continuous investment in R&D, we honor the journey of 3D printing by pushing its limits forward.

Frequently Asked Questions

Who invented 3D printing and when?

Charles Hull is credited with inventing the first commercial 3D printer in 1986 using stereolithography. Earlier conceptual work by Hideo Kodama in 1981 laid the foundation.

What were the first materials used in 3D printing?

Early 3D printers primarily used UV-sensitive resins (SLA) and later introduced thermoplastics (FDM) and powdered polymers (SLS).

When did consumer 3D printers become available?

Affordable desktop 3D printers emerged in the mid-2000s following the expiration of FDM patents, notably through open-source projects like RepRap.

How has the cost of 3D printer production changed over time?

The cost of 3D printer production has significantly decreased for desktop models, while industrial systems have become more cost-effective relative to their advanced capabilities.

What is the future of 3D printer manufacturing?

Future trends include AI-powered print prediction, sustainable bio-materials, and fully automated manufacturing lines integrating 3D printers into Industry 4.0 environments.

From Prototype Dreams to Industrial Reality: The Living History of 3D Printer Production

The history of 3D printer manufacturing is not a closed chapter—it’s a living narrative, constantly rewritten by technological breakthroughs, market demands, and visionary engineers. By understanding its past, professionals can better forecast its future and participate in the next wave of transformative manufacturing.