- Konu Başlıkları

- Phase 1: Conception, Design, and Rigorous Prototyping

- Phase 2: Sourcing and Supply Chain Excellence

- Phase 3: Precision Assembly and Integration

- The Assembly Line

- Phase 4: Rigorous Testing and Quality Assurance

- Phase 5: Packaging, Distribution, and Post-Sale Support

- The Role of Erlas Global in 3D Printer Manufacturing

- Conclusion: The Blueprint of Innovation

- Frequently Asked Questions About 3D Printer Manufacturing

Have you ever wondered about the intricate journey a 3D printer takes from a mere concept to the revolutionary device sitting on a desktop or a factory floor? It's a fascinating process, blending cutting-edge engineering, precision manufacturing, and rigorous quality control. Understanding the 3D printer manufacturing process offers valuable insight into the complexity and innovation behind additive manufacturing itself. For tech students, engineers, and anyone curious about the inner workings of these machines, delving into their creation reveals a world of meticulous design and strategic assembly.

[widget-131]

Phase 1: Conception, Design, and Rigorous Prototyping

Every 3D printer begins its life long before any physical components are made. This initial phase is all about innovation, market analysis, and meticulous planning. Our team at Erlas Global starts by identifying market needs or specific technological advancements to drive the development of new 3D printer models.

- Research & Development (R&D): This involves exploring new printing technologies, material compatibility, user interface improvements, and structural designs that enhance performance and reliability.

- Conceptual Design: Engineers and industrial designers work together to sketch initial concepts, outlining the printer's overall form, key functionalities, and aesthetic appeal.

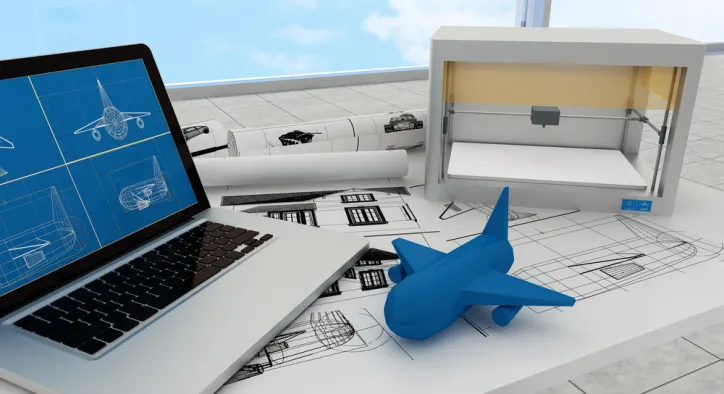

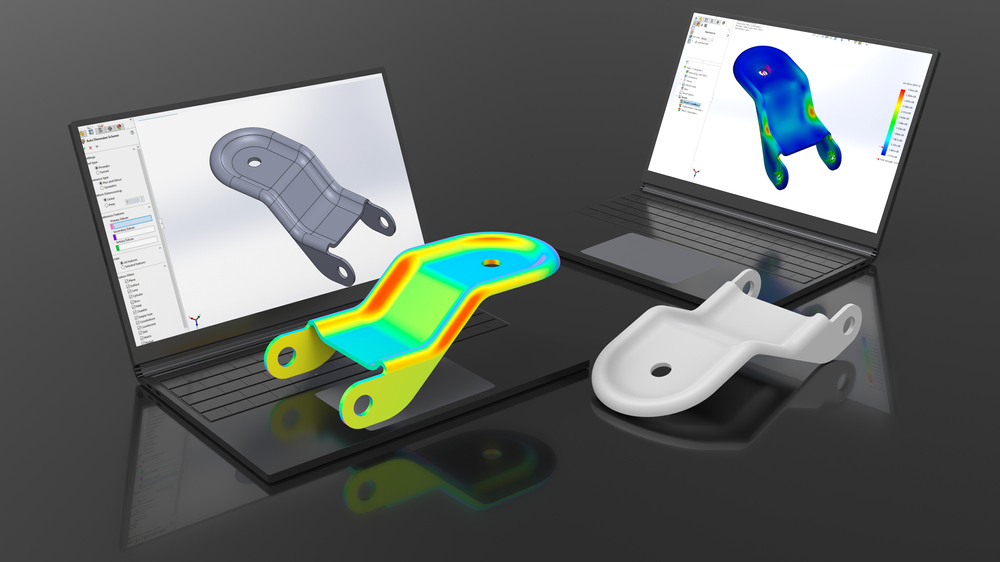

- Computer-Aided Design (CAD) Modeling: Detailed 3D models of every single component, from the frame to the smallest screw, are created using advanced CAD software. This digital blueprint serves as the master plan for the entire production process.

- Component Selection: Critical parts like stepper motors, hot ends, extruders, control boards, and specialized sensors are chosen. This selection is based on performance, durability, cost-effectiveness, and compatibility with the overall design.

- Rapid Prototyping and Iteration: Before committing to mass production, functional prototypes of the printer or its critical sub-assemblies are built and exhaustively tested. This involves creating and evaluating multiple iterations to identify and rectify any design flaws, optimize functionality, and ensure the printer meets all performance criteria. This iterative process is crucial for refining the design and reducing risks in later stages.

This design phase is where the foundation for a high-quality 3D printer is laid. It's a testament to the expertise required, where every decision impacts the final product's efficiency and user experience. Our commitment at Erlas Global is to ensure that this stage is executed with unparalleled precision and foresight.

Phase 2: Sourcing and Supply Chain Excellence

With the design finalized, the next critical step in 3D printer production is sourcing the hundreds, sometimes thousands, of individual components. This isn't just about buying parts; it's about managing a complex global supply chain to ensure consistent quality, competitive pricing, and timely delivery. Effective supply chain management is a cornerstone of efficient manufacturing, particularly in a high-tech industry like 3D printing.

- Global Supplier Network: We work with a diverse network of specialized suppliers worldwide for everything from custom-machined metal parts and injection-molded plastic components to advanced electronic circuits and optical systems.

- Quality Assurance for Components: Each incoming component undergoes stringent quality checks to ensure it meets our specifications. This proactive approach prevents defects from being integrated into the final product.

- Inventory Management: Strategic inventory planning ensures a steady flow of parts to the assembly line, minimizing delays and optimizing production schedules. This is crucial for controlling the overall cost of 3D printer production and meeting delivery targets.

A robust and resilient supply chain is vital, as disruptions can significantly impact production timelines and costs. Our experience in this area allows us to navigate complexities and maintain consistent output.

Phase 3: Precision Assembly and Integration

This is where the 3D printer truly comes to life. The assembly phase involves bringing together all the meticulously sourced components on a highly organized production line. The level of automation varies depending on the scale of production and the complexity of the printer, but precision is always paramount.

The Assembly Line

Our assembly lines are designed for efficiency and accuracy. While some repetitive tasks might be handled by robotics for speed and consistency, skilled human technicians play a crucial role in complex integrations and final adjustments. Typical steps include:

- Frame Construction: Assembling the printer's structural frame, which provides stability and houses all internal components.

- Motion System Installation: Integrating critical components like stepper motors, linear rails, lead screws, and belts that enable the precise movement of the print head and build platform. This step demands extreme accuracy for accurate prints.

- Extruder and Hot End Assembly: Building the core of the printing system, including the extruder mechanism that feeds the filament and the hot end that melts it.

- Electronics and Wiring: Installing the main control board, power supply, wiring harnesses, and various sensors. This requires careful attention to detail to prevent electrical shorts and ensure proper communication between components.

- Firmware Flashing: Loading the printer's operating system (firmware) onto the control board, enabling it to interpret G-code and control hardware functions.

- Final Enclosure Assembly: Attaching the exterior panels, doors, and other protective or aesthetic elements.

Every connection, every alignment, and every screw is critical. Even minute misalignments can lead to print quality issues or machine malfunctions, emphasizing the importance of rigorous attention to detail throughout the entire 3D printer assembly process.

Phase 4: Rigorous Testing and Quality Assurance

Manufacturing a 3D printer is not complete until it undergoes extensive testing and passes stringent quality assurance protocols. This phase is non-negotiable, ensuring that every printer leaving our facility meets the highest standards of performance, reliability, and safety.

- Functional Testing: Each printer undergoes a series of functional tests to verify that all mechanical, electrical, and software components operate as intended. This includes checking motor movements, heating elements, cooling fans, and sensor readings.

- Calibration & Alignment: Precise calibration of axes, bed leveling, and extrusion rates are performed to ensure optimal print accuracy and consistent output.

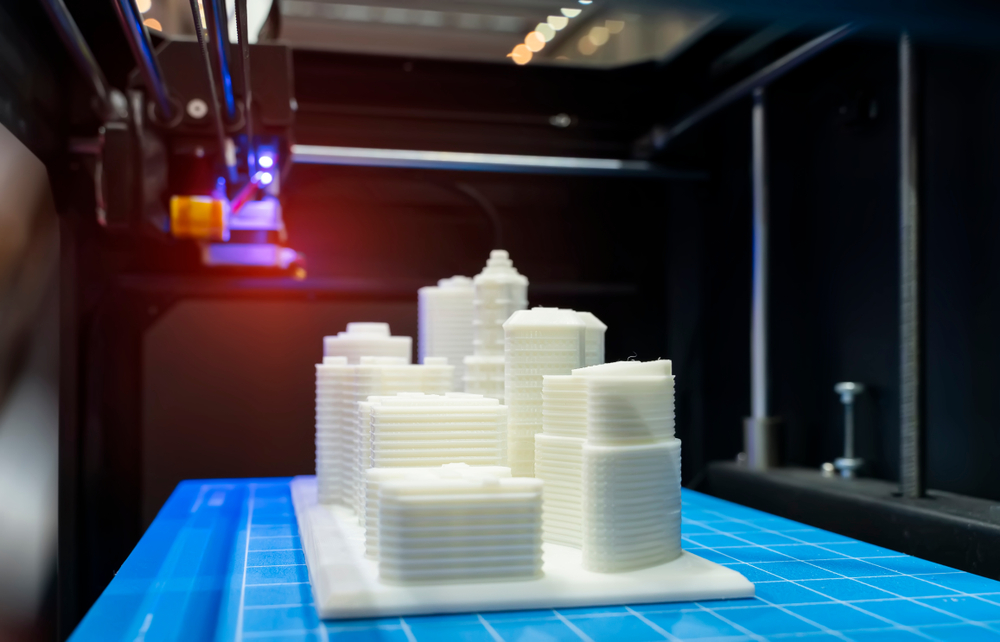

- Test Prints: Standardized test models are printed on each machine to evaluate print quality, layer adhesion, dimensional accuracy, and common printing artifacts. This real-world test provides invaluable data on performance.

- Safety Checks: All electrical connections, thermal management systems, and emergency shut-off mechanisms are thoroughly inspected to comply with international safety standards.

- Long-Term Reliability Testing: A sample of printers may undergo extended operational tests to simulate prolonged use, identifying any potential weaknesses or durability concerns under continuous operation. This commitment ensures the long-term reliability users expect.

Only after passing all these exhaustive checks is a 3D printer deemed ready for packaging and distribution. This multi-layered quality control approach is a hallmark of our dedication to delivering superior products, a factor that sets Erlas Global apart in the field of 3D printer production.

Phase 5: Packaging, Distribution, and Post-Sale Support

The final stages focus on getting the manufactured 3D printer safely into the hands of its users and providing ongoing support.

- Protective Packaging: Custom-designed packaging ensures the printer is protected from shocks, vibrations, and environmental factors during transit, minimizing the risk of damage.

- Logistics & Distribution: Efficient warehousing and global logistics networks are utilized to distribute the printers to regional distributors, retailers, or directly to end-users worldwide.

- Post-Sale Support: Our commitment extends beyond the point of sale. We provide comprehensive customer service, technical support, warranty services, and access to spare parts. This ensures continuous operation and customer satisfaction, building lasting relationships and reinforcing our reputation for trust and expertise.

This holistic approach to manufacturing, from the drawing board to post-sale care, defines the lifecycle of a high-quality 3D printer. It's a journey fueled by innovation and a relentless pursuit of perfection.

The Role of Erlas Global in 3D Printer Manufacturing

At Erlas Global, our expertise in the full lifecycle of 3D printer production positions us as a leading partner for businesses and innovators. We don't just follow a process; we constantly refine it, integrate the latest technologies, and uphold the highest standards of quality.

- Advanced Facility & Technology: Our state-of-the-art manufacturing facility is equipped with advanced machinery and automation, enabling precision and efficiency at scale.

- Experienced Engineering Team: Our team of seasoned engineers and technicians brings extensive experience in additive manufacturing hardware development, ensuring expert execution at every stage.

- Custom Solutions: Beyond standard models, we specialize in bespoke 3D printer development, allowing clients to order custom 3D printer prototypes and specialized systems tailored to unique industrial or research needs. This flexibility is a key differentiator.

- Commitment to Quality & Reliability: We pride ourselves on the durability and performance of our manufactured printers, backed by rigorous testing and a dedication to long-term customer satisfaction.

Our commitment is to empower the future of manufacturing by producing the tools that make it possible. By understanding and mastering every nuance of 3D printer manufacturing, we deliver products that are not just functional but truly exceptional.

Conclusion: The Blueprint of Innovation

The manufacturing of a 3D printer is a testament to modern engineering and industrial prowess. It’s a multi-stage journey from a digital design to a physical product, each step demanding precision, expertise, and a commitment to quality. From the initial conceptualization and the rigorous testing of prototypes to the meticulous assembly, comprehensive quality control, and thoughtful post-sale support, every element contributes to the creation of a reliable and high-performance machine.

For those looking to leverage the power of additive manufacturing, understanding this intricate process illuminates the value behind a well-engineered 3D printer. It underscores why choosing a manufacturer with proven experience, robust quality control, and a comprehensive understanding of the entire production lifecycle, like Erlas Global, is essential for unlocking the full potential of this transformative technology.

Frequently Asked Questions About 3D Printer Manufacturing

- What is the most challenging part of manufacturing a 3D printer?

One of the most challenging aspects is ensuring precise alignment and calibration of all mechanical and electronic components to achieve consistent, high-quality prints. Managing a complex global supply chain for specialized parts also presents significant challenges. - How long does it take to manufacture a 3D printer?

The manufacturing timeline varies widely depending on the type and complexity of the printer. Desktop FDM printers can be assembled relatively quickly (hours to days per unit in bulk), while large industrial or custom-built printers can take weeks or even months from initial design to final testing. - Are 3D printers built using automation?

Yes, modern 3D printer manufacturing facilities increasingly utilize automation and robotics for repetitive assembly tasks, component testing, and quality control to improve efficiency, precision, and consistency, especially in high-volume production. - What are the main types of materials used in 3D printer construction?

3D printers are typically constructed from various materials, including aluminum extrusions or steel for frames, injection-molded plastics for casings, specialized alloys for hot ends, various polymers for belts and gears, and advanced electronics for control boards and wiring. - Do manufacturers perform test prints on every 3D printer?

Yes, reputable manufacturers perform thorough functional testing, which includes running standardized test prints on every single 3D printer unit before it is packaged. This ensures that each machine meets performance and quality standards.