- Konu Başlıkları

- Understanding 3D Printer Production

- Step-by-Step: The 3D Printer Production Process

- 1. Digital Design with CAD Software

- 2. File Conversion and Slicing

- 3. Material Selection

- 4. Calibration and Printer Setup

- 5. Printing Process

- 6. Post-Processing and Finishing

- What Are the Key Technologies in 3D Printer Production?

- FDM (Fused Deposition Modeling)

- SLA (Stereolithography)

- SLS (Selective Laser Sintering)

- DMLS/SLM (Direct Metal Laser Sintering)

- Production vs. Prototyping: What’s the Difference?

- How Much Does 3D Printer Production Cost?

- A Glimpse Into Erlas Global’s Expertise

- Final Thoughts: Understanding the Full Journey of 3D Printer Production

- Frequently Asked Questions

The term 3D printer production often brings to mind futuristic machines turning digital ideas into physical reality. But what does this process actually entail? For students, engineers, and curious minds stepping into the world of additive manufacturing, understanding the entire 3D printer production pipeline—from concept to completed print—is essential.

Whether you're exploring the fundamentals for academic interest or considering how this technology applies to real-world industries, this guide will break down the complete production process, highlight key technologies, and share insights from professionals like those at Erlas Global.

[widget-131]

Understanding 3D Printer Production

At its core, 3D printer production refers to the complete workflow required to create objects using additive manufacturing technologies. Unlike subtractive manufacturing—which cuts away material from a solid block—3D printing builds an object layer by layer, following a digital blueprint.

The process involves more than just hitting 'print'. It includes steps like:

- Digital design and modeling

- File slicing

- Material selection

- Printer calibration

- Layer-by-layer fabrication

- Post-processing and quality inspection

Depending on the complexity of the object, material requirements, and intended use, each step in this process requires attention, precision, and technical knowledge.

Step-by-Step: The 3D Printer Production Process

Let’s explore each stage of the 3D printing journey in detail.

1. Digital Design with CAD Software

Every 3D printed object starts with a digital model. Engineers and designers typically use CAD (Computer-Aided Design) software to create a 3D representation of the object. This model defines geometry, size, and sometimes material properties.

Common tools include Fusion 360, SolidWorks, and Blender. For beginners, free tools like Tinkercad or SketchUp also work.

2. File Conversion and Slicing

Once the model is complete, it's exported as an STL (stereolithography) or OBJ file. But 3D printers can’t interpret these files directly. That’s where slicing software comes in.

The slicer converts the 3D model into thin horizontal layers and generates G-code, a set of machine instructions that tell the printer how to move, extrude, and form each layer.

Parameters defined in this stage include:

- Layer height

- Infill density

- Print speed

- Support structure placement

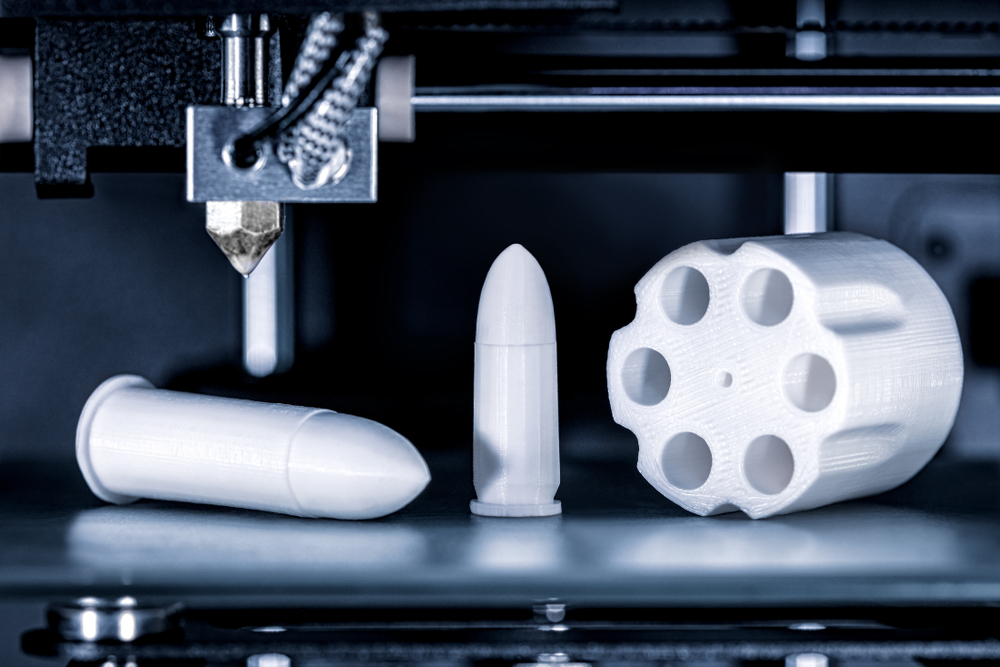

3. Material Selection

Choosing the right material is critical. There are many available depending on the printing technology and application:

- PLA (Polylactic Acid): Easy to print, biodegradable, great for prototypes

- ABS (Acrylonitrile Butadiene Styrene): Tough and heat-resistant

- PETG (Polyethylene Terephthalate Glycol): Combines strength and flexibility

- Resins: Used in SLA printers for detailed models

- Nylon, TPU, and composites: For flexible or load-bearing parts

- Metal powders (steel, titanium): For industrial-grade end-use parts

Professional providers like Erlas Global help clients select the optimal material for mechanical performance, thermal tolerance, or aesthetic quality.

4. Calibration and Printer Setup

Before printing begins, calibration ensures the printer is correctly aligned and extruding consistently. This involves:

- Leveling the print bed

- Setting the correct nozzle and bed temperatures

- Checking filament feed paths

- Testing extrusion width

Experienced technicians verify these details to avoid print failures and ensure high-quality output.

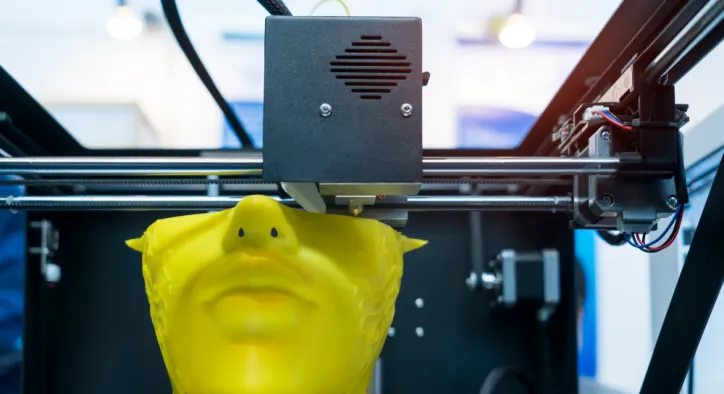

5. Printing Process

Once setup is complete, the actual fabrication begins. Here, the printer builds the object layer by layer, guided by the G-code instructions. The print time varies depending on object size, material, and resolution settings.

A prototype ring might print in 30 minutes, while a complex drone housing could take over 12 hours.

For larger-volume applications, 3D printer production involves high-capacity industrial machines capable of producing multiple units simultaneously.

6. Post-Processing and Finishing

After printing, many objects require additional work to reach their final form. This stage can include:

- Removing supports

- Sanding and smoothing

- Curing (especially for resins)

- Painting or coating

- Assembly of multiple printed parts

At Erlas Global, post-processing is performed with precision to meet customer specifications—whether it's a functional prototype or a final product ready for market launch.

What Are the Key Technologies in 3D Printer Production?

Understanding the major 3D printing technologies can help you choose the right method for your project.

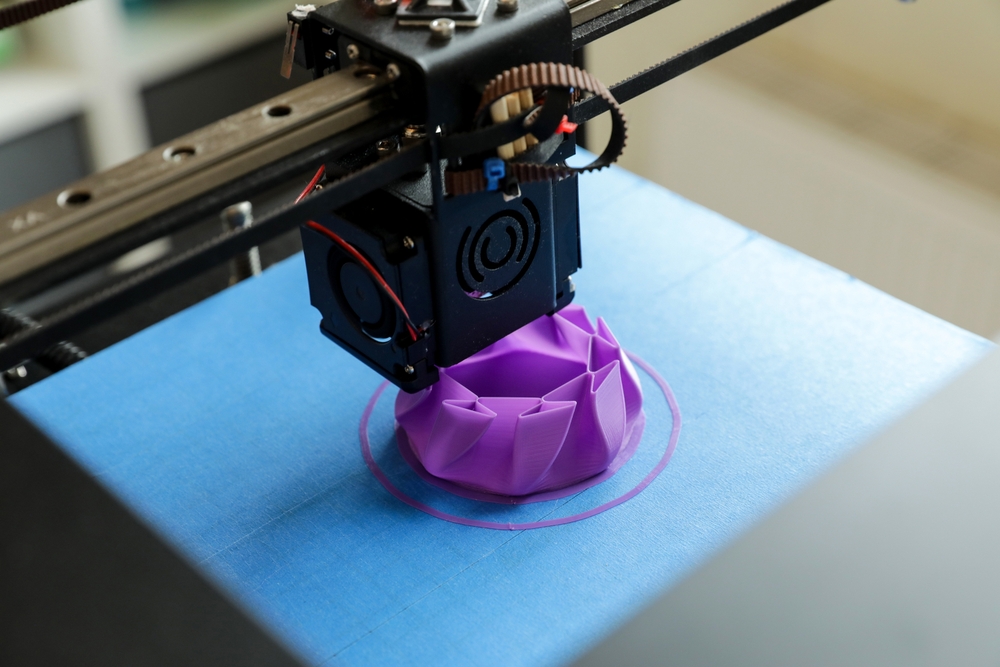

FDM (Fused Deposition Modeling)

Most common and budget-friendly. Great for basic prototyping using thermoplastic filaments.

SLA (Stereolithography)

Uses liquid resin cured by lasers. High detail and smooth finishes—ideal for jewelry, dental models, and small intricate parts.

SLS (Selective Laser Sintering)

Fuses powdered material using lasers. Suitable for functional parts that need strength and flexibility.

DMLS/SLM (Direct Metal Laser Sintering)

Used in aerospace, automotive, and medical sectors to print functional metal parts directly.

Each method requires different materials, post-processing, and design considerations. Erlas Global's production team helps clients match their needs with the appropriate technology.

Production vs. Prototyping: What’s the Difference?

While 3D printing started as a tool for prototyping, it's now commonly used in actual production. The difference lies in:

- Prototyping: One-off or iterative models to test shape, fit, or usability.

- Production: Creating finished parts for use or sale, often in small or medium batches.

Thanks to process optimization, it's now possible to order custom 3D printer prototypes and then scale the same design into small production runs—all with minimal delays or design revisions.

How Much Does 3D Printer Production Cost?

Costs vary based on factors like:

- Part size and geometry

- Print resolution

- Material used

- Required finishing

- Production volume

For instance, printing a small PLA prototype may cost under $50, while a metal part with tight tolerances and post-processing can reach hundreds or even thousands.

To understand the full breakdown of expenses, Erlas Global provides transparent quotes through its cost of 3D printer production resource page.

A Glimpse Into Erlas Global’s Expertise

Erlas Global is not just a print shop—it’s a full-service partner in additive manufacturing. Their experience spans industries from consumer products to industrial machinery.

Their in-house team provides:

- Custom design consultation

- Multi-technology production capabilities

- Fast prototyping turnaround

- Scalable small-batch manufacturing

- Stringent quality control

Clients value their responsiveness, technical guidance, and ability to deliver functional prototypes that transition smoothly into production.

Final Thoughts: Understanding the Full Journey of 3D Printer Production

3D printer production is more than pushing a button—it’s a detailed, multi-step process involving creativity, engineering, and precision. From concept design to final assembly, each phase plays a role in achieving successful results.

Whether you're a student starting a passion project or a brand innovating in a competitive market, understanding this production cycle helps you make smarter, more efficient choices. Erlas Global stands ready to guide you every step of the way with their rich technical experience, flexible services, and commitment to quality.

Frequently Asked Questions

What is the main advantage of 3D printer production over traditional manufacturing?

The primary advantage is flexibility. 3D printing allows for rapid prototyping, customization, and small-batch production without the need for expensive tooling. This means designers and engineers can iterate more often, reduce waste, and bring products to market faster.

How accurate are 3D printed parts?

Accuracy depends on the technology and machine used. High-resolution SLA printers, for example, can produce details as fine as 25 microns. Industrial FDM and SLS machines also offer tolerances within ±0.1 mm, making them suitable for functional applications.

Can 3D printed parts be used in final products?

Yes, especially with the right material and finishing. Many industries now use 3D printed parts in end-use applications—especially when volumes are low, customization is key, or time-to-market is critical.

Is 3D printer production environmentally friendly?

While not entirely waste-free, 3D printing typically produces less waste than subtractive manufacturing. Additionally, the ability to print on demand reduces overproduction and material surplus. Some filaments are also biodegradable or recyclable.

How do I know which 3D printing technology is right for my project?

Choosing the right method depends on your part's purpose, strength requirements, budget, and aesthetic preferences. FDM is great for drafts, SLA for visual models, and SLS for durable functional parts. Erlas Global’s team helps clients make informed decisions based on these parameters.