- Konu Başlıkları

- Why 3D Printing is Revolutionizing Industries

- Customization and Flexibility

- Cost and Time Efficiency

- Sustainability

- Key Applications of 3D Printer Production

- Automotive Industry

- Healthcare and Medical Devices

- Aerospace and Defense

- Fashion and Consumer Goods

- Education and Research

- Case Studies: Real-World Impact

- Emerging Trends in 3D Printing Applications

- Challenges and Solutions

- Frequently Asked Questions (FAQs)

- What industries benefit most from 3D printer production?

- How does 3D printing improve prototyping?

- Is 3D printing sustainable for industrial applications?

- Unlocking the Potential of 3D Printing

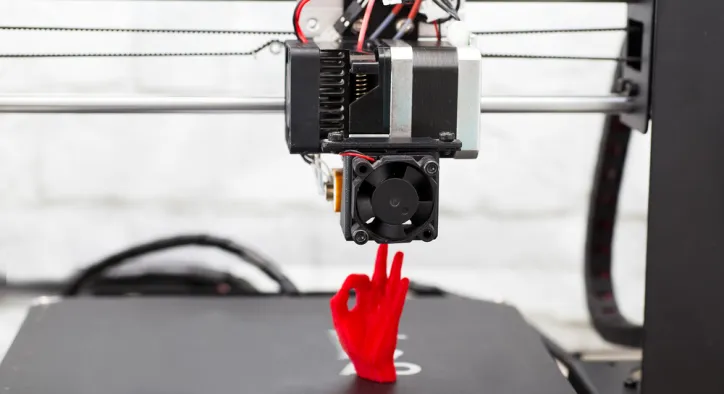

3D printing, or additive manufacturing, has transformed industries by enabling rapid prototyping, customization, and efficient production. The 3D printer production applications span diverse sectors, from automotive to healthcare, offering innovative solutions to complex challenges. This comprehensive guide explores how 3D printing is applied across industries, highlighting real-world use cases and emerging trends for industry professionals and innovators.

Why 3D Printing is Revolutionizing Industries

3D printing’s ability to create complex geometries, reduce waste, and accelerate production makes it a game-changer. This section outlines the key advantages driving its adoption across sectors.

Customization and Flexibility

Uses of 3D printing in industry include producing tailored components, from medical implants to automotive parts. Unlike traditional manufacturing, 3D printing allows for on-demand customization without costly retooling.

Discover how 3D printing services enable customized production.

[widget-131]

Cost and Time Efficiency

By reducing material waste and streamlining prototyping, 3D printing lowers production costs and shortens development cycles. For example, prototyping a part can take hours instead of weeks.

Learn more about production cost savings with 3D printing.

Sustainability

Additive manufacturing minimizes material usage and supports eco-friendly materials like biodegradable PLA, aligning with sustainability goals.

Key Applications of 3D Printer Production

3D printing is applied across mainstream and niche industries, delivering measurable benefits. Below are the most impactful use cases.

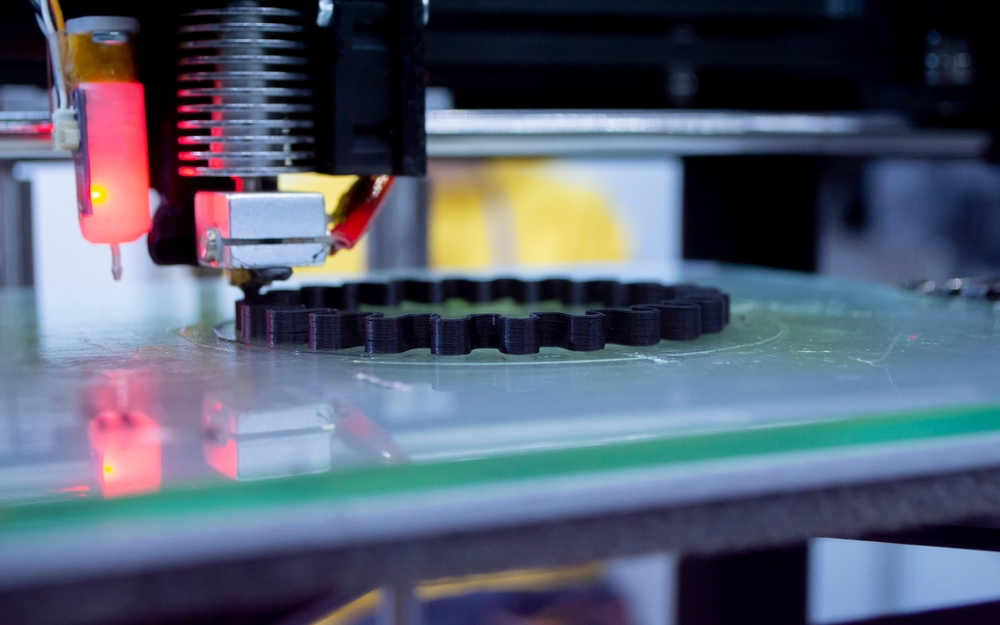

Automotive Industry

3D printing in healthcare and automotive is transformative. In automotive, 3D printing produces lightweight components, such as engine parts and interior panels, reducing vehicle weight by up to 20%. Companies like BMW use 3D printing for rapid prototyping and low-volume production.

Start with custom prototypes to test automotive designs.

Healthcare and Medical Devices

3D printing creates patient-specific implants, prosthetics, and surgical guides. For instance, dental labs produce custom crowns with SLA printers, improving fit and reducing costs. FDA-approved biocompatible materials ensure safety.

Aerospace and Defense

3D printing in aerospace enables lightweight, complex parts like turbine blades. Aerospace giants like Boeing use 3D printing to reduce part weight by 30%, improving fuel efficiency. ISO standards ensure compliance for critical components.

Fashion and Consumer Goods

3D printing in fashion allows designers to create intricate jewelry, footwear, and accessories. Adidas, for example, uses 3D-printed midsoles for customized sneakers, enhancing comfort and sustainability.

Education and Research

3D printing in education supports hands-on learning by producing models for engineering, biology, and architecture students. Universities leverage 3D printing for research, creating prototypes for experimental devices.

Case Studies: Real-World Impact

Erla’s Global’s portfolio showcases 3D printing’s transformative potential. A healthcare client used their 3D printing services to produce 1,000 custom prosthetics, reducing costs by 40%. In automotive, a partner achieved a 25% faster prototyping cycle for electric vehicle components, demonstrating efficiency gains.

Emerging Trends in 3D Printing Applications

3D printing continues to evolve, unlocking new possibilities. Key trends include:

- 4D Printing: Self-transforming materials that adapt to environmental changes.

- Bioprinting: Printing tissues and organs for medical research.

- Construction: 3D-printed buildings using concrete printers.

Challenges and Solutions

Despite its benefits, 3D printing faces challenges:

- Material Limitations: Use advanced materials like carbon-fiber composites.

- Scalability: Invest in automated print farms for high-volume production.

- Regulatory Compliance: Partner with experts to meet FDA or ISO standards.

Frequently Asked Questions (FAQs)

What industries benefit most from 3D printer production?

Automotive, healthcare, aerospace, fashion, and education benefit significantly. For example, automotive uses 3D printing for lightweight parts, while healthcare produces custom implants, each leveraging 3D printing’s customization and efficiency.

How does 3D printing improve prototyping?

3D printing accelerates prototyping by producing parts in hours, reducing costs and enabling rapid iterations. For instance, automotive companies can test multiple designs in days, improving product development efficiency.

Is 3D printing sustainable for industrial applications?

Yes, 3D printing reduces material waste and supports eco-friendly materials like PLA. Automated systems further enhance efficiency, making it a sustainable choice for industries like fashion and consumer goods.

Unlocking the Potential of 3D Printing

3D printer production applications continue to redefine industries, from automotive to education, by enabling customization, efficiency, and innovation. With Erla’s Global’s expertise, businesses can harness these capabilities to stay ahead in competitive markets. Ready to explore 3D printing for your industry? Dive into these insights and start innovating today.