- Konu Başlıkları

- Project Background

- Production Process

Mask production is also very fast and easy with CNC printer and 3D printing. Modeling can be done on innovative models or classic designs. It is possible to make a difference with customization opportunities, material quality and long-lasting designs. If we take a closer look at the anti-fog mask printing process patented by Protofab and prepared with 3D production:

Project Background

For 3D printing mask production, the focus was on using high-quality polypropylene, being resistant to temperatures, soft and flexible, comfortable and easy to carry, durable and providing high breathability.

The material selection was made after the design evaluation. The combination of silicone and soft polypropylene, which will meet the requirements, durability and thermal resistance of the mask while ensuring that it can be worn comfortably, was preferred. Then, production was started after the other details of the design were clarified.

Production Process

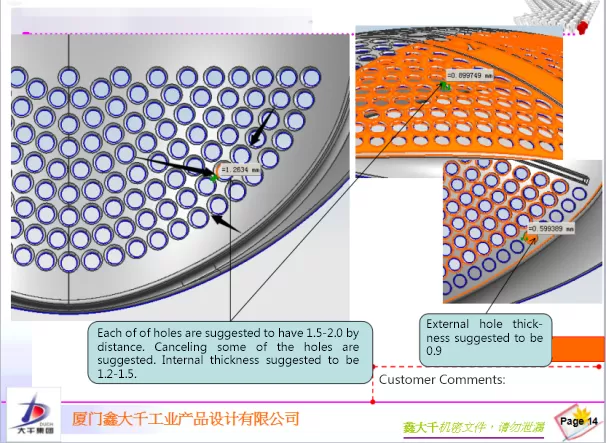

Since we can produce the product and model you want thanks to 3D printing technologies, all we need to do is transfer the design to the preferred production machine. After the CNC milling, CNC machining and EDM wire cutting stages, we obtain the anti-fog mask. After the polishing process, the anti-fog mask is ready with the assembly.

Contact us to get information about the production of anti-fog masks with CNC printing and to share your 3D printing projects.